Reducing microbial contamination via sterile risk assessment

Posted: 20 April 2015 |

Several years ago, microbiologist Guenther Gapp created a new sterile risk assessment tool (based on a hazard operability analysis [HAZOP] approach) to identify and reduce the microbial contamination and compliance risk of aseptically-produced sterile products and production plants. The following article describes the operating principle of three risk analysis tools with a special focus on the revised 2015 edition. This latest edition incorporates the improvements that have been implemented in recent years, which make the tool more applicable and thus valuable for the user.

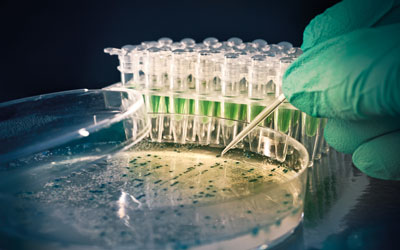

Microorganisms are omnipresent in the environment, making sterile manufacturing plants, especially those with aseptic filling operations, highly vulnerable to microbial contamination. There are a variety of potential root causes of non-sterile results. These may include weaknesses of design, insufficient maintenance of the production plant or poor aseptic working practices of the cleanroom operators, to name but a few. Also, it is often unclear as to whether a lack of sterility is due to a systematic weakness of the process or if it has been caused by the often-cited ‘single incidence’ resulting from an individual human error. As the non-homogenous distribution of contaminants within the product gives rise to low reproducibility when testing, it makes the search for an assignable cause even more complex and hides the impact it may have.

Since only a small number of random samples are examined for sterility testing, the statistical significance of the results is hardly sufficient to draw conclusions about the sterility of the whole batch. Thus, neglecting appropriate precautions would ultimately create a very high risk for the patient. Therefore, it is imperative to understand all possible microbial entry points and to implement quality risk management (QRM) strategies that aim to prevent microbial contamination…

The rest of this article is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here