UV contamination control robot shows pharma cleanroom promise

Posted: 21 October 2025 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

Efficacy research supports the widespread use of autonomous UVC disinfection for microbial surface decontamination, say AstraZeneca microbiology experts.

An autonomous ultraviolet-C (UV-C) robot has shown potential for the digitalised, chemical-free surface decontamination of micro-organisms on various cleanroom surfaces in pharma manufacturing facilities.

A team of microbiology experts at AstraZeneca tested the light source against a range of organisms representing most major types of environmental contaminants as well as those most seen in the pharma company’s own cleanrooms.

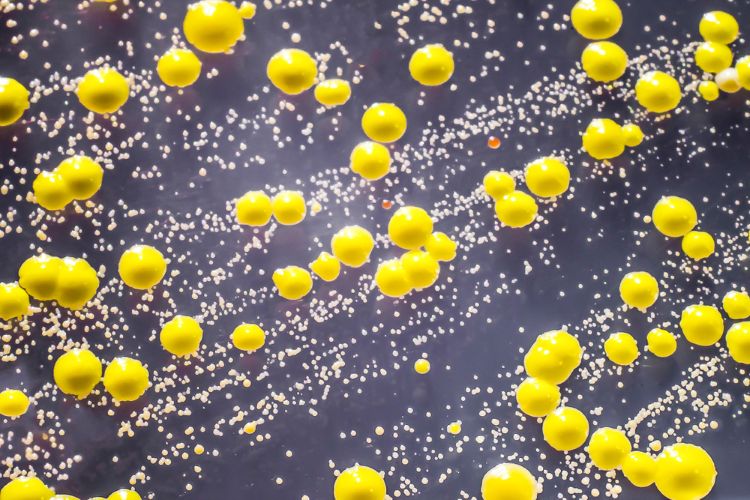

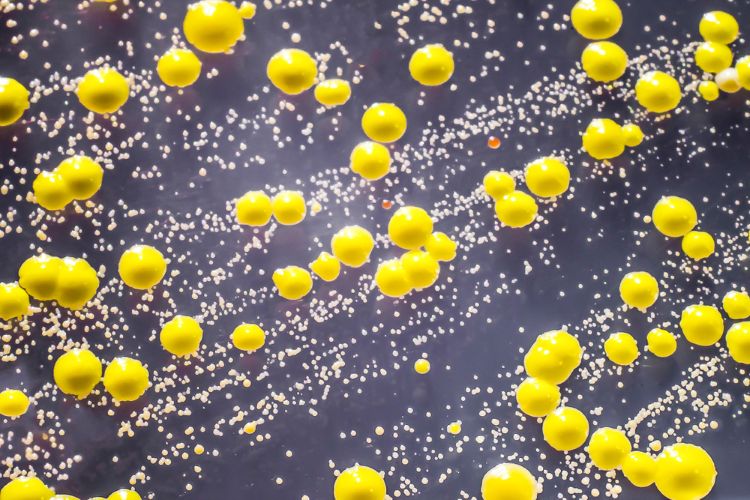

They included a panel of five American Type Culture Collection (ATCC) organisms (Pseudomonas paraeruginosa, Staphylococcus aureus, Bacillus spizizenii, Candida albicans and Aspergillus brasiliensis) as well as the environmental isolates Micrococcus luteus, Moraxella osloensis, Bacillus Cereus and Penicillium chrysogenum).

One of the main challenges of microbial bioburden control in pharmaceutical cleanrooms is “the prevalence of resistant organisms and the regulatory demand for evidence-based, reproducible surface disinfection”, Capper et al said.

The team found that the UV-C robot was suitable for use and could achieve a 3-log reduction for bacteria and 2-log reduction for spores depending on the dose applied.

However, they noted that in this type of environment autonomous UV-C robots would require “thorough qualification… to demonstrate equivalence or superiority to traditional chemical disinfectants, adhering to regulatory standards”.

Efficacy of the autonomous UV-C disinfection robot

The authors employed a standing robot tower that allowed light to shine directly on to the coupon, while also providing remote access to switch on the light and measure the dose and time.

Capper et al. performed a bench study based on the Surface Challenge Test Method EN 13697 to evaluate the reduction in microbial viability after an inoculated surface was exposed to a light source emitting 254nm UV-C energy.

The inoculated coupons were then irradiated with the UV-C light to determine the required dose to reach the desired log reduction as per USP<1072> for disinfectant efficacy.

The authors recommended using the UV-C robot adjunctively – “not as a sole disinfection method, in clean rooms, with clear protocols for addressing its known limitations (surface occlusion, variable spore reduction)”.

the UV‑C robot “reliably achieved ≥3‑log reduction for vegetative bacteria and yeast at 100 mJ/cm²”

Karen Capper, Senior Director Microbiology Science & Technology at AstraZeneca, told EPR that overall, the UV‑C robot “reliably achieved ≥3‑log reduction for vegetative bacteria and yeast at 100 mJ/cm²”.

She added: “We found for spore efficacy a dose‑dependent approach was the best option, needing ~200 mJ/cm² for Bacillus and up to 500 mJ/cm² for resilient moulds.

“As expected, material effects were modest, with stainless steel slightly favourable. Micrococcus luteus showed borderline resistance at 100 mJ/cm², and bovine serum albumin, expected to protect Gram‑negatives during drying, reduced apparent recovery post‑UV. The study supports UV‑C as very useful addition to chemical disinfection and a good addition to contamination control for clean rooms.”

The paper was published in EJPPS.

Related topics

Big Pharma, Data Analysis, Lab Automation, Manufacturing, Microbiology, Mould contamination, Robotics, Technology