Ingenza invests in faster fermentation development

Posted: 11 September 2017 | Ingenza | No comments yet

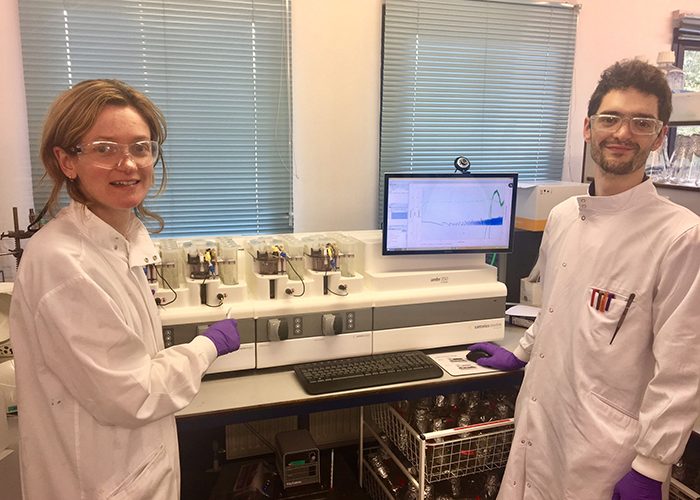

Leading industrial biotechnology company Ingenza has acquired a high performance benchtop bioreactor system to enable faster development of new fermentation processes…

The Sartorius ambr® 250 modular system combines automated operation and monitoring with small-scale, single-use fermentation vessels, offering potential benefits across the business.

This compact instrument is designed to fit seamlessly into laboratory fermentation workflows, helping to accelerate development timelines. Alison Arnold, Head of Fermentation Development at Ingenza, explained:

“As a pioneer in the industrial biotech sector, we have been involved in the development of this innovative system since the early days, first in a consultancy capacity and later as a beta tester. There is nothing else on the market that combines the resource savings of a miniaturised bioreactor platform with the speed and convenience of fully disposable reaction vessels. This offers big savings in terms of set-up and clean down times – eliminating the latter completely – freeing up many hours of staff time.”

“Investment in this modular technology will allow us to more quickly develop new fermentations in 100-250 ml vessels, without any loss of data, before scaling up to traditional five litre fermentations for further testing. We have already tested the system with a number of our established in-house fermentation processes – including fed-batch, high cell density E. coli and Pichia fermentations – achieving very high cell densities and growth curves that correlate extremely well with our well-characterised five litre fermentations. This gives us complete confidence that new processes developed on the ambr 250 system can be successfully scaled up for production, helping us to deliver faster results for our customers.”

For more information, visit www.ingenza.com or email [email protected]