Measurement of heavy metals in cannabis vaping aerosols: a practical assessment

Posted: 21 April 2021 | Robert Thomas (Scientific Solutions) | No comments yet

In light of the increased popularity of cannabis vaping in the United States, new regulations in the state of Colorado assert the need to test for heavy metal contaminants. Here, Robert Thomas explains the reasons for this pressing need and the challenges it presents.

A RECENT announcement by the state of Colorado proposed that all marijuana concentrates in electronic cannabis delivery systems (ECDS) must be tested for heavy metal contaminants in the emitted aerosol.1 This is long overdue, since it was first reported in 2017 that vaping liquids were exhibiting high levels of metals in the vaped aerosols.2 Despite causing some concern, the problem was not fully investigated, except to ascertain that the metals were likely coming from the internal components. However, the dangers of vaping resurfaced in 2019 when 67 deaths occurred as a result of severe respiratory failure from vaping devices containing vitamin E acetate, one of the diluents used in these systems.3 The problem was eventually resolved by removing this compound from the ingredients in all legally produced vaping products. Colorado has been very proactive in this field and as a result became the first state to require testing cannabinoid vaping aerosols for a panel of metal contaminants. This announcement has stimulated significant interest from other state regulators waiting to see how this eventually gets resolved. Here, we investigate the challenges of implementing these regulations.

Fundamentals of vaping

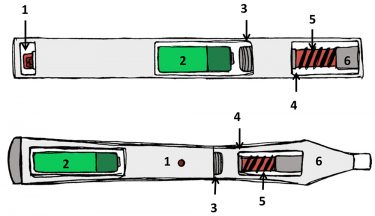

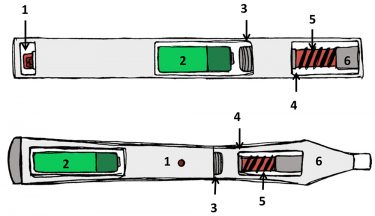

Figure 1: Basic components of two common cannabis vaping pen designs (www. glennaelisabeth.com)

1. Power button/Voltage control; 2. Battery; 3. Threaded adapter to remove/replace

components; 4. Sensor; 5. Tank/atomiser; 6. Nicotine/cannabinoid extract cartridge.

When cannabis (extract or flower) is heated to 200‑300°C the psychoactive and therapeutic cannabinoid components volatilise into tiny airborne droplets that form an aerosol called a vapour, which is inhaled by the user. The process is carried out using a battery‑powered element to heat the cannabis product in a tank that is often mixed with diluent liquids, like vegetable glycerin, to decrease its viscosity and sometimes flavourings to increase its appeal to younger users. In single-use cartridges, the liquid is often soaked into fibres and a heating element is wound around a wick. In pods, the liquid is usually in direct contact with the heating element, while in refillable systems, users add their desired liquid into a tank. In some devices, the temperature can be selected using variable voltage control. As a result, it is extremely difficult to predict what metals will find their way into the aerosol. A schematic of two typical vaping pens is shown in Figure 1.

There are several studies in the public domain describing the analysis of e-liquids.4 However, very little has appeared on charactering aerosols, mainly due to the many different materials used inside commercially-available systems. For example, some of the common components being used for tanks include plastic, glass (Si, Na, B) or stainless steel (Fe, Cr, Ni, Co, Mn), while coils and atomisers come in a variety of materials including nichrome (Ni, Cr), kanthal (Fe, Cr, Al), sometimes with brass electrical connectors (Cu, Zn, Pb) or other materials. Some of the newer atomisers are also made from ceramic materials (Si, Al, Ca).

Analysing vaping liquids for heavy metals

The standard method used to trap and collect the vapour from ENDS or ECDS is with an aerosol generation machine”

It is important to emphasise that the Colorado directive specifically stipulates characterising the vaping aerosol for heavy metals, not just the liquid. Sampling an aerosol without contaminating the sample presents an order of magnitude greater complexity, because the aerosolisation mechanism and transport of metallic particles at vaping temperatures around 200-300°C are very different to sampling metal ions in solution. Moreover, once the aerosol has been generated, there must be a way to trap and collect the aerosol without additional contamination in order to measure the metal content by inductively coupled plasma mass spectrometry (ICP-MS). In comparison, sampling a vaping liquid is fairly straightforward, as it can just be sampled directly from the refillable pod or vaping device tank. The diluents used in the device will dictate what types of solvents to use for dilution. With electronic nicotine delivery systems (ENDS), the diluents are typically propylene glycol or vegetable glycerin, which are water soluble (hydrophillic). This means that they can be extracted and dissolved using a mixture of mineral acids and, provided the calibration standards are made up in a similar matrix, can be presented to the ICP-MS for analysis.5 However, vaping devices used for cannabinoids are more complex to sample because the diluents might also include medium chain triglyceride (MCT) oil, which is not water soluble (hydrophobic), in addition to the cannabinoid extract itself, which is oily and very viscous in nature. This means the liquid must be extracted and dissolved in an organic solvent, which will present problems for the ICP-MS instrument unless an optimised sample introduction system is used. The alternative approach is to use a microwave digestion system to redissolve the residue in an acid mixture, before being presented to the instrument for analysis.

Characterising vaping aerosols for heavy metals

It is important to emphasise that the transport of the metal particles in a vaping aerosol is not fully understood, but will be different based on the metal compositions of vaping device components and their heating characteristics. The temperatures at which ENDS/ECDS liquids are heated (200-300°C) are insufficient for vaporisation of most metals and metal oxides; therefore, the mechanism of transport in the aerosol is likely to be independent of metal volatility.6 Moreover, limited entrainment of metal particles, or dissolved metal compounds in aerosol droplets formed by passage of air over the liquid surface, will have an impact on the metal transport mechanism. As a result, the principal forms of the metals would not vaporise at the relatively low heating element temperatures, but rather be inefficiently entrained and transported in the aerosol.6,7 For this reason, spiking trace elements into the liquid and measuring recoveries in the collected aerosol as a way of validating the method is unlikely to be a useful exercise.

The standard method used to trap and collect the vapour from ENDS or ECDS is with an aerosol generation machine, which is an adaption of traditional smoking machines used to measure contaminants in tobacco products like cigarettes and cigars. These aerosol generation-testing machines work extremely well for measuring organic analytes, but have limitations when it comes to evaluating inorganic pollutants because many of the components, such as tubing, filters and impingers, are not made of high purity materials. Consequently, researchers who are interested in looking at very low levels of trace metals in e-cigarette aerosols must typically customise the aerosol generation machines to make them better suited for investigating trace metals.

Vaping aerosol collection

If vaping aerosol analyses are to provide robust data, the methodologies and instrumentation must be scientifically valid. While no vaping machine puffing regimen mimics a human vaper, it is imperative that the data collected follows a standard and reproducible procedure. There are two standard methods available:

- ISO Standard – Method, 20768:2018 was specifically developed for the routine testing of cannabinoid vapour products with an analytical vaping machine8

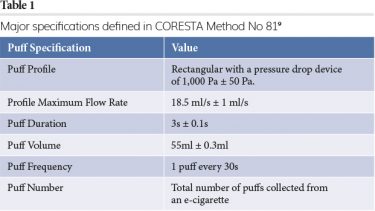

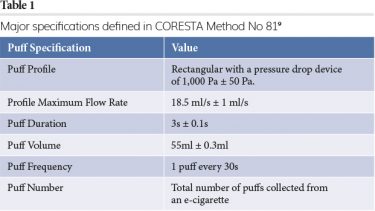

- The other method is the CORESTA Method 81,9 which defines the requirements for the generation and collection of e-cigarette aerosol for analytical testing purposes.

They are both similar in functionality, but the CORESTA method has been more widely used because of its application with tobacco and nicotine vaping products. Both methods have similar specifications, including prescribed limits for pressure drops, puff volume, puff time and puff profile for the generation and collection of reproducible aerosol results.

NOTE: It is important to emphasise that the CORESTA 81 Method was developed for tobacco and nicotine products, so the puff specifications reflect a typical cigarette smoker or END consumer. We know that cannabis consumers use ECDS very differently with regard to duration, volume, frequency, and number of puffs. For that reason, specifications must be developed specifically for cannabis vaping systems to ensure the data can be validated under standardised testing conditions. The specifications of CORESTA Method 81 are shown in Table 1.

Figure 2: A typical 8-port aerosol testing machine (www.glennaelisabeth.com).

There are many different aerosol vaping testing systems on the market that can deliver these specifications. An example is shown in Figure 2, which is the Cerulean CETI 8 – an 8-port aerosol testing machine that can accommodate up to eight different e-cigarettes or vaping devices.10

Once the device has gone through its testing protocol and the condensate has been trapped, collected and analysed by ICP-MS, the weight of each element in nanograms (ng) in the collected aerosol is then calculated based on the number of puffs tested. A common unit to compare different ENDS or ECDS is typically ng/10 puffs or ng/50 puffs, depending on the type of product being tested and the purpose of the analysis.

Collecting hydrophobic liquids

As mentioned previously, analysing liquids from ENDS and ECDS is a fairly seamless dilute and shoot method using a nitric acid/hydrochloric acid mixture, because diluents like propylene glycol and vegetable glycerin are hydrophillic. Even liquids from ECDS are not over complicated because the cannabinoid oils and diluents like MCT oil can either be diluted with a suitable organic solvent or the oils can be digested in a microwave digestion system. However, to sample an aerosol containing different oils and cannabinoids (ie, hydrophillic and hydrphobic in nature) is an order of magnitude more difficult. Filters tend to become clogged by viscous condensates and there is a strong likelihood that the collected material will be oily in nature, which might require an organic solvent to ensure it will also maintain the metallic contaminants in solution.

the uncertainty about how these devices will be tested might encourage the industry to design vaping devices with more inert materials that are unlikely to corrode, or even develop systems that are free of metal components”

This was exemplified by the trapping methodology described in a recent publication by Pappas and colleagues, which is based on a modification of the method used for ENDS.11,12 The modification of this method for oily ECDS aerosols includes an initial tubing rinse with diethylene glycol monoethyl ether (DEGMEE). This solvent has low volatility, is an excellent solvent for oils, and is water soluble. In this study, DEGMEE dissolves and dilutes the oil droplets from up to 50 CORESTA Method 81 vaping puffs as it passes through the condensation tube into a 50mL polymethyl pentene (PMP) volumetric flask. The remnant in the condensation tube is then followed by multiple rinses with two percent v/v nitric acid and one percent v/v hydrochloric acid into the same 50mL flask, and dilution to 50mL with the same acid solution. Since DEGMEE is both oil and water soluble, it emulsifies the oil with the aqueous acid for analysis. Calibration standards are prepared in two percent v/v nitric acid, one percent v/v hydrochloric acid and 10 percent DEGMEE for the purpose of matrix matching with the same solution obtained after rinsing aerosol metals from the condensation tube.

So there are definitely analytical challenges to characterising ECDS aerosols for elemental contaminants by ICP-MS. Without question, carrying out quantitation of low-level impurities requires knowledge and experience of working in the ultra-trace environment, particulary when the sample matrix is hydrophillic and hydrphobic in nature, and requires specialised sampling stratergies. These are not insurmountable hurdles to overcome, but in light of the many novice users in cannabis testing labs who are not well versed in the complexities of the ICP-MS technique, these issues can easily lead to errors and inaccuracies that could result in false positive and false negative results.

Final thoughts

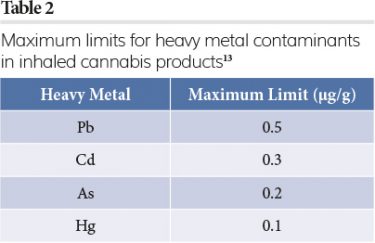

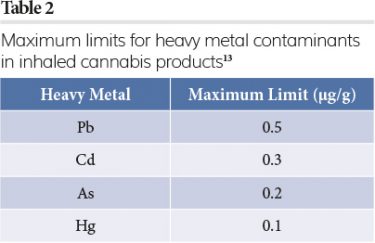

Currently, the regulated limits of the traditional “big four” heavy metals in inhaled cannabis products in the majority of the 36 US states where cannabis is legal are shown in Table 2.13

So what should be included in a panel of elements for ECDS aerosols? Clearly the point of testing vaping devices is to find out what toxic substances are being corroded and transported to the user. Assuming the cannabinoid extracts have been tested for the state required panel and are below the maximum allowable limits, if any of these other elements show up in the device aerosol, they will most probably have come from the vaping process. It would therefore be perfectly valid to include all the likely metal candidates to the regulated list for the state, based on the design of the vaping device, but it is not yet clear what limits should be set for those additional elements. Only time will tell, but other states are watching these new Colorado regulations very closely and possibly looking to add this to their list of regulations in the near future. In addition, the uncertainty about how these devices will be tested might encourage the industry to design vaping devices with more inert materials that are unlikely to corrode, or even develop systems that are free of metal components.

About the author

Robert Thomas, Principal Consultant at Scientific Solutions. Rob has worked in the field of atomic and mass spectroscopy for more than 45 years, including 24 years for a manufacturer of atomic spectroscopic instrumentation. Rob has written over 100 technical publications, including a 15-part tutorial series on ICP-MS. He is also the editor and frequent contributor of the Atomic Perspectives column in Spectroscopy magazine. In addition, he has authored five textbooks on the fundamental principles and applications of ICP-MS. His most recent book published in October 2020 focuses on the measurement of heavy metal contaminants in cannabis and hemp. Rob has an advanced degree in analytical chemistry from the University of Wales, UK, and is also a Fellow of the Royal Society of Chemistry (FRSC) and a Chartered Chemist (CChem).

Acknowledgements

This article has been summarised from the author’s recent book entitled “Measuring Heavy Metal Contaminants in Cannabis and Hemp”, ISBN 9780367417376, with the permission from CRC Press, Boca Raton, FL. https://www.routledge.com/Measuring-Heavy- Metal-Contaminants-in-Cannabis-and-Hemp/ Thomas/p/book/9780367417376

References

- Colorado to Require Cannabis Vapor Testing by 2022, L. Bear-McGuiness , Analytical Cannabis, October 15, 2020, https://www.analyticalcannabis.com/news/colorado-to-require-cannabis-vapor-testing-by-2022-312726

- Heavy Metal Contaminants from Cannabis Vaporizer Cartridges: Valid Concern or Blowing Smoke? Afia I, Weltman R, Boyar K. CannMed Conference, September 2019: https://www.researchgate.net/publication/336070263_Heavy_Metal_Contaminants_from_Cannabis_Vaporizer_Cartridges_Valid_Concern_or_Blowing_Smoke

- Outbreak of Lung Injury Associated with the Use of E-Cigarette, or Vaping, Products, Center for Disease Control and Prevention (CDC) Website: https://www.cdc.gov/tobacco/basic_information/e-cigarettes/severe-lung-disease.html

- Lead and Other Toxic Metals Found in E-Cigarette Vapors, Olmedo P, et al. Johns Hopkins Bloomberg School of Public Health, February 7, 2017, https://www.jhsph.edu/news/news-releases/2017/study-toxic-metals-found-in-e-cigarette-liquids.html

- Analysis of Toxic Metals in Liquid from Electronic Cigarettes, Gray N, et al. International Journal of Environmental Research and Public Health, 2019;16: doi: 10.3390/ijerph16224450.

- Analysis of Toxic Metals in Electronic Cigarette Aerosols Using a Novel Trap Design, Halstead M, et al. Journal of Analytical Toxicology, 2020;44:149–155.

- Toxic Metal-Containing Particles In Aerosols from Pod-Type Electronic Cigarettes. Pappas RS, et al. Journal of Analytical Toxicology, 2020; doi: 10.1093/jat/bkaa088.

- ISO Method, 20768:2018, Vapor Products – Routine Analytical Vaping Machine – Definitions and Standard Conditions, https://webstore.ansi.org/Standards/ISO/ISO207682018?gclid=EAIaIQobChMI2r70-6Ls7AIVHOy1Ch329wcKEAAYASAAEgIQA_D_BwE

- CORESTA Recommended Method Number 81, Routine Analytical Machine for E-Cigarette Aerosol Generation and Collection – Definitions and Standard Conditions, June, 2015, https://www.coresta.org/sites/default/files/technical_documents/main/CRM_81.pdf

- Cerulean CETI 8 E-cigarette vaping instrument (8 Channel), https://www.cerulean.com/en/solutions/product/ceti-8-range

- Analysis of Toxic Metals in Electronic Cigarette Aerosols Using a Novel Trap Design, Halstead M, et al. Journal of Analytical Toxicology, 2020;44:149–155.

- Measurement of Elemental Constituents of Vaping Liquids and Aerosols with ICP-MS. Pappas RS, et al. in R.J. Thomas, Measuring Heavy Metal Contaminants in Cannabis and Hemp, CRC Press, 2020, ISBN 9780367417376.

- The Status of US States’ Legalization of Medical Marijuana, https://medicalmarijuana.procon.org/legal-medical-marijuana-states-and-dc/

Issue

Related topics

Cannabinoids, Drug Delivery Systems, Drug Safety, Material Identification, QA/QC, Regulation & Legislation