Water-based reactors offer pharmaceutical industry a safer alternative to toxic solvents

Posted: 17 February 2025 | European Pharmaceutical Review | No comments yet

The breakthrough promises to transform pharmaceutical manufacturing by enabling chemical reactions in water, reducing reliance on hazardous organic solvents.

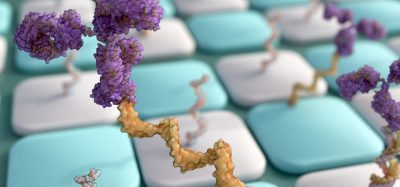

A new water-based reactor system, developed by scientists at Rice University, promises to bring significant advances to pharmaceutical manufacturing. By using specialised nanostructures called micelles, the technology allows chemical reactions to take place in water, rather than relying on potentially harmful and toxic solvents such as dicholoromethane and toluene.

The innovation beckons a major shift in industrial chemistry, helping companies to reduce solvent waste, improve workplace safety, and lower production costs.

Micelles – how the technology works

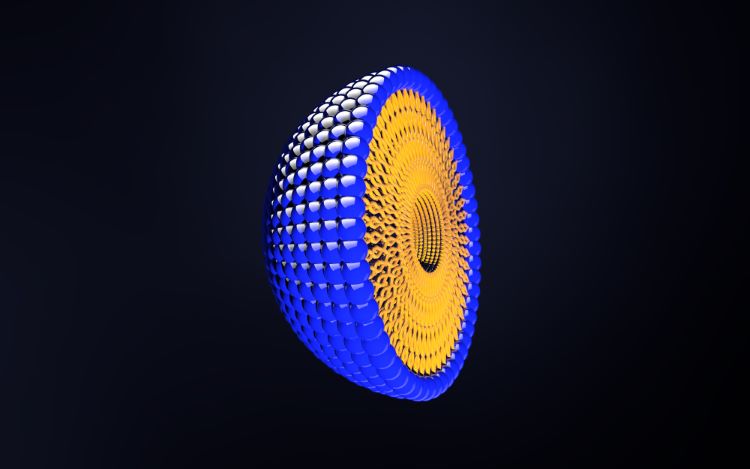

Researchers designed metal complex surfactants (MeCSs) that self-assemble into nanoscale spheres. These micelles, just five to six nanometres in size, provide an enclosed environment where chemical reactions can occur efficiently, even with substances that typically do not dissolve in water.

A key advantage of this system is its ability to facilitate photocatalytic reactions – processes that use light to drive chemical transformations – without relying on hazardous solvents. This capability makes the micellar reactor system particularly valuable for pharmaceutical applications, where precise and controlled reactions are essential.

A greener future for the pharmaceutical industry

These micelles act like tiny reaction vessels. They enable chemical transformations that wouldn’t normally work in water while being more sustainable than traditional methods”

Ying Chen, the study’s first author and a doctoral chemistry student at Rice, explained the potential impact of the technology: “These micelles act like tiny reaction vessels. They enable chemical transformations that wouldn’t normally work in water while being more sustainable than traditional methods.”

By eliminating the need for volatile organic solvents, this approach significantly reduces harmful emissions and waste, making it an attractive option for industries seeking greener production methods.

Adopting water-based micellar reactors could dramatically cut down on the pharmaceutical industry’s reliance on hazardous solvents, which are costly to dispose of and pose health risks to workers. In addition, the micelles are potentially reusable, offering further advantages in terms of both cost and waste management.

Looking ahead, the researchers aim to refine and scale up the technology for industrial use. If widely adopted, water-based reactors could revolutionise drug manufacturing, making it cleaner. safer, and more sustainable.

The findings were published in Chemical Science.

Related topics

Clinical Development, Drug Development, Drug Manufacturing, Formulation, Manufacturing, Nanoparticles, Research & Development (R&D), Sustainability, Technology, Therapeutics