Raman-based PAT tool could advance continuous vaccine manufacturing

Posted: 30 October 2025 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

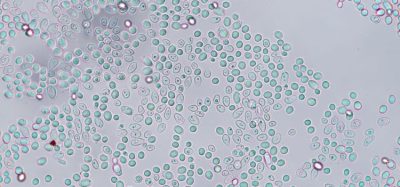

Study demonstrates the non-invasive tool’s potential for real-time monitoring of cytomegalovirus (CMV) viral particles.

A new Raman spectroscopy-based process analytical tool can continuously monitor vaccine quality during production, according to researchers from Purdue University and Merck Sharp & Dohme Corp.

Utilising rapid monitoring and analysis could help pharmaceutical companies boost vaccine production, Athalye et al. stated.

Co-author Shreya Athalye explained that “current methods are more time-consuming and offline”. However, the findings showed that the proposed quality control tool can operate online, yielding results in 30 seconds or less, making it an efficient and economical approach for vaccine production.

the proposed quality control tool can operate online, yielding results in 30 seconds or less, making it an efficient and economical approach for vaccine production”

In their study, the process analytical technology (PAT) tool successfully measured the quality and quantity of continuously flowing viral particles, specifically human cytomegalovirus (CMV). The research team stated that to their knowledge their study is the first to illustrate a Raman spectroscopy-based PAT tool for detecting CMV particles.

“CMV structure and mode of action make the vaccine development challenging, but many investigational vaccines are being evaluated in clinical trials,” Athalye noted.

Employing Raman spectroscopy as a “nondestructive” technique meant the team could use samples with water, making it “ideal for biological samples such as vaccines,” Athalye said.

Co-author Mohit Verma shared that PAT “holds the potential to enable rapid release of biologics”, of which a robust PAT is “critical component of continuous manufacturing”, stated Athalye.

“By demonstrating that we’re able to characterise CMV at industrially relevant concentrations and flow rates, we support easier adoption of this approach in biomanufacturing,” Verma added.

Overall, the PAT tool offers improved quality control through continuous monitoring during the production process. The study findings can be applied to other viral particles and bioprocesses, according to the researchers. Athalye et al. also acknowledged the study represents a proof-of-principle for advancing PAT development in large molecules.

Set to be published in Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy.

Related topics

Analytical techniques, Big Pharma, Data Analysis, Industry Insight, Manufacturing, Process Analytical Technologies (PAT), Production, QA/QC, Research & Development (R&D), Technology