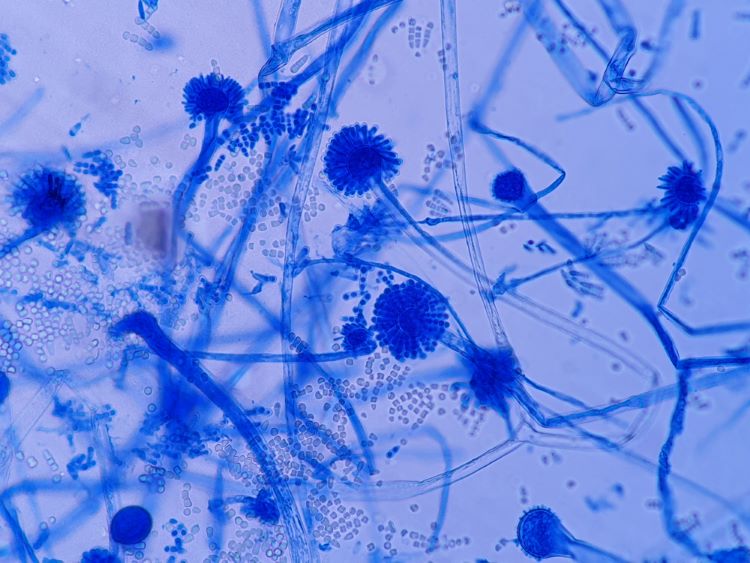

Pharma Horizons: environmental monitoring

This exclusive report addresses the key obstacles and innovations shaping pharmaceutical environmental monitoring, from QC and contamination control, to the impact of advanced technologies and regulatory changes. Discover practical solutions you can implement to drive progress for your organisation.