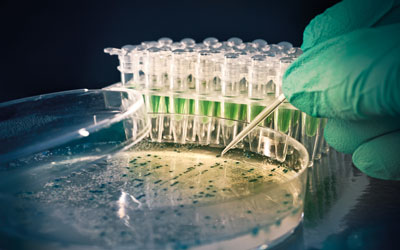

Overview of rapid microbiological methods evaluated, validated and implemented for microbiological quality control

The risk for patients through spoiled or otherwise adulterated pharmaceuticals…

19 April 2011 | By Oliver Gordon, Jennifer C. Gray, Hans-Joachim Anders, Alexandra Staerk & Oliver Schlaefli, Novartis Pharma Stein AG and Gunther Neuhaus, University of Freiburg

The risk for patients through spoiled or otherwise adulterated pharmaceuticals has been acknowledged for many centuries and led to the establishment of Good Manufacturing Practice (GMP) and pharmacopoeial guidelines. Besides chemical purity, pharmaceuticals also have to meet microbiological standards, the latter primarily depending on the administration route. Drug products which…