The importance of labelling compliance for pharma

Posted: 17 February 2020 | Bart Vansteenkiste (Domino Printing Sciences) | No comments yet

Bart Vansteenkiste explains why it is important to validate pharmaceutical labelling compliance to ensure good manufacturing practice.

Validation impacts every process and component of pharmaceutical production, including machines, systems, equipment and computer systems. A large part of the validation and compliance process is in the documentation – there needs to be integrated support for documentation with complete clarity and traceability.

In today’s supply chain, the printer is arguably the final element in the validation process and with regulatory complexity increasing, not to mention industry-wide movement towards last-minute production processes, organisations cannot afford to omit this final stage of compliance.

However, the unfortunate reality is that many organisations do not realise their printer validation packs are incomplete and therefore not meeting US Food and Drug Administration (FDA) regulatory requirements. With the considerable risk and implications of non-compliance, Bart Vansteenkiste outlines how pharmaceutical companies can ensure their User Requirement Specification (URS) covers the final element of the production process.

Market context

The risk of non-compliance is significant. From the potential regulatory fines and loss of brand reputation, to the temporary forced shutdown of a full production line and cost of remediating the situation, not having validated systems and processes in place could have a potentially catastrophic impact on any business.

Every pharmaceutical manufacturer will be aware of the requirement for GMP validated products and processes, whereby the company must demonstrate in a documented form that the processes, methods, tests, activities and equipment they utilise are capable of repeatedly producing the desired product. Therefore, each critical step in the manufacturing procedure must be validated to perform as intended under defined conditions.

The documentation associated with validation includes:

- Standard operating procedures (SOPs)

- Specifications

- Validation master plan (VMP)

- Qualification protocols and reports

- Validation protocols and reports.

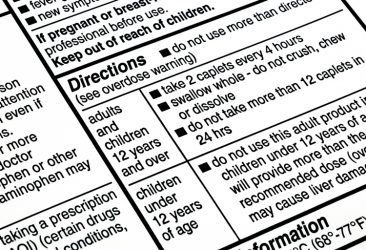

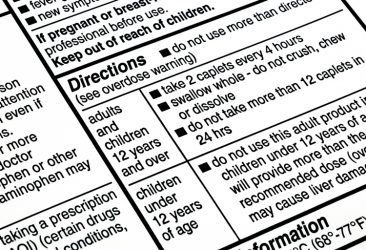

Critical components

Labelling and label printing are critical final components of the validation process. In 2018, nine percent of all medical device recall events – and the return of over a million units – were due to labelling issues, with printing errors undoubtedly a factor. It only takes one stray label, instructions for use (IFU) or printing error to cause a product recall. A trivial issue like a faulty print ribbon, for example, can lead to missing, unreadable or misinterpreted content. When this goes undetected and products reach the supply chain, regulations are breached and patient safety is put at risk. Moreover, with an increasing shift towards just-in-time production processes, organisations need to ensure they have robust mechanisms in place to assure batch integrity. Of concern, most organisations are unlikely to realise that their printing systems do not comply, until regulators come knocking.

Good manufacturing practice (GMP) validation is an essential element of quality assurance”

The most reliable suppliers will be proactive in ensuring system validation, checking that what is required in the URS is delivered without error; providing a risk assessment; test strategy; good document standards and training protocols. A dedicated, good automated manufacturing practice (GAMP) V trained expert will know exactly what is needed to achieve validation in a pharmaceutical production environment, including validating any additional systems’ integration – such as a labelling or enterprise resource planning (ERP) system – and will provide the validation pack to support that.

It is ever more important that a company’s printing systems’ rationale can stand up to the scrutiny of an audit. So why leave the compliance of the final component of the validation processes to chance?

About the author

Bart Vansteenkiste is the Life Science Sector Manager of Domino Printing Sciences. With an engineering background, Bart has over 18 years of experience in advising manufacturers on how to best meet their coding requirements.