Glove prints are the most effective microbiological monitoring method during aseptic handling, finds study

Researchers evaluate the various microbiological monitoring (MM) methods employed inside a laminar airflow or safety cabinet in hospital pharmacies.

According to a new study, the glove print microbiological monitoring (MM) method is the most informative during aseptic handling inside a laminar airflow or safety cabinet (LAF/SC) in hospital pharmacies.

In the study published in the European Journal of Pharmaceutical Sciences, researchers sought to evaluate the different kinds of MM and media fills used for environmental and process control during the aseptic handling of sterile products in hospitals.

The authors also discuss methods used for evaluating and assessing MM results – in this study, they compared colony forming units (cfu) and Contamination Recovery Rate (CRR; the rate at which MM samples contain any level of contamination -USP<1116>-).

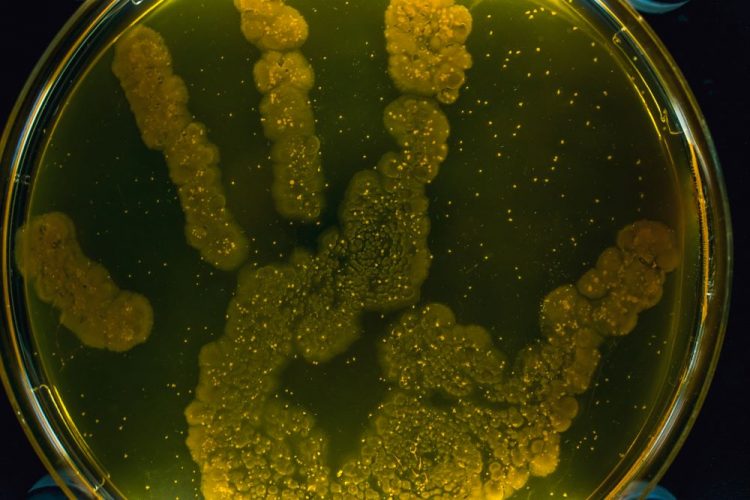

In the study, the researchers looked at four different MM methods: air sampling using settle plates, glove print 5 fingers using settle plates, worktop surface using contact plates and outer surface of materials with a non-sterile surface using contact plates. Assessing them over a period of two years at four different hospitals.

The authors explained that for many reasons the utility of active air sampling is doubtful. They said that it is not advised, as it presents an additional risk of contamination; produces wide confidence intervals for sample sizes like that of the study, making meeting the required contamination level for air inside a LAF/SC by viable air sampling very difficult to achieve; and that, because they are working in a closed system, the risk of air as a source of non-sterility is low anyway.

According to the team, contact plates are the best method for surface monitoring even if the surface is not flat, as swabs need additional laboratory handling before samples can be incubated.

The scientists also said that studies have shown that touch by gloved hands has been found to be the greatest risk of non-sterility. Because of this, they advise that keeping the surface bioburden of these gloves as low as possible, as well as monitoring this surface, is extremely important. This is what makes glove prints the most informative of all MM methods, according to the researchers.

With regards to glove prints, they explained that sampling of the non-dominant may be more important than sampling of the dominant hand because, while the dominant hand touches instruments, the non-dominant hand could touch the tip of the syringe or needle and the non-dominant hand holds disinfected ampoules and vials.

The authors also concluded that of the two measurements of non-sterility used in the study, CRR is the best for assessing the results of MM inside, or related to, working in LAF/SC. Additionally, they suggest that A CRR of <10 percent is a realistic limit for MM during aseptic handling in hospital pharmacies and that a rolling CRR, calculated using the last 100 samples, should provide a good compromise between the reliability of the CRR value and timely prediction of process changes.