Address the time-to-result challenge posed by short shelf-life radiopharmaceuticals.

20 November 2025 | 3:00 PM GMT | FREE Virtual Panel Discussion

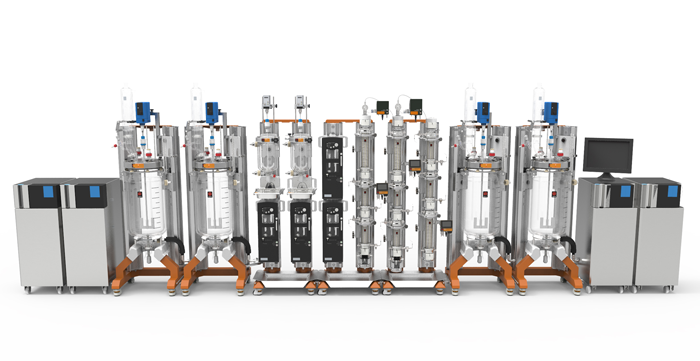

This webinar showcases the Growth Direct System; an RMM (Rapid Microbial Method) that improves on traditional membrane filtration, delivering increased accuracy, a faster time to result, enhanced data integrity compliance, and more control over the manufacturing process.

Key learning points:

- Understand the benefits of full workflow microbiology quality control testing automation in radiopharmaceutical production

- Learn about ITM’s implementation journey and considerations when evaluating the technology

- Find out how the advanced optics and microcolony detection capabilities of Growth Direct® technology impact time to result (TTR).

Don’t miss your chance to learn from experts in the industry – Register for FREE