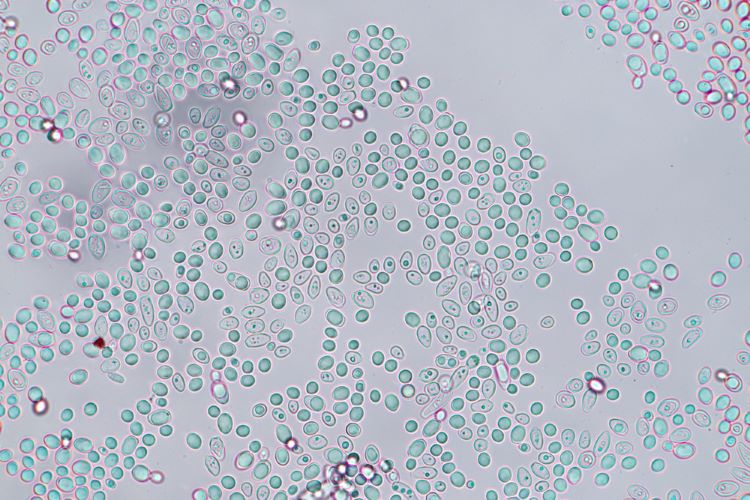

When innovative formulations cloud sterility testing

30 October 2024 | By Charles River

Webinar presented by Miriam Guest, Senior Principal Scientific Advisor at Charles River, to explore how ATP-bioluminescence outperforms traditional sterility testing in complex matrices.