Handling HPAPIs safely – what does it take?

Posted: 9 March 2023 | Catherine Eckford (European Pharmaceutical Review), Kishore Hotha (Veranova) | No comments yet

Here, Veranova’s Global Head of Analytical Research & Development, Dr Kishore Hotha, outlines safety considerations when manufacturing and handling highly potent APIs (HPAPIs).

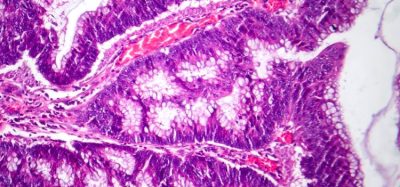

Highly potent active pharmaceutical ingredients (HPAPIs) are used in formulations for high potent drugs, owing to their ability to target precise disease cells including cancer cells.1 These substances “are pharmacologically and biologically active at low doses,” Dr Kishore Hotha, Global Head of Analytical Research & Development at Veranova, explained.

In this Q&A, Dr Hotha offered expertise on the requirements and challenges of handling HPAPIs during manufacture.

He shared that the HPAPI market is expected to grow significantly in the next five years. Observing trends in the sector, Hotha noted: “the pharmaceutical regulatory space is shifting from traditional drug therapies to emerging targeted therapies that need specialised handling and considerations.”

What are the current trends of HPAPIs?

The pharmaceutical regulatory space is shifting from traditional drug therapies to emerging targeted therapies that need specialised handling and considerations.”

Highly potent APIs are pharmacologically and biologically active compounds at low doses. There are emerging trends in oncology, with new chemical entities (NCEs) and antibody-drug conjugates (ADC) leading to increased demand for HPAPI manufacturing capabilities. The pharmaceutical regulatory space is shifting from traditional drug therapies to emerging targeted therapies that need specialised handling and considerations. The compounds require special handling due to their cytotoxicity in the NCEs and investigational new drug applications (INDs). Based on the latest report and data, HPAPI market size is expected to reach $32 billion by 2028.1

What are the challenges companies face in identifying and assessing the toxicity and potency of HPAPIs?

The primary challenge for CDMO/biotech companies is to classify the API with all the necessary data for the Occupational Exposure Limit (OEL), Occupational Exposure Band (OEB) potency, and toxicity. The lower the OEL limit, the higher the potency, which demands rigorous containment and controls. For the NCEs with no established OEL, the risk assessment process and strategy should be worked out by reviewing preclinical study results, third-party assessment by toxicology and environment, health and safety (EHS), literature searches, and AMES/genotoxic assessments. Biotechs working with early-stage NCEs must adopt a conservative approach to prioritise safety for their HPAPIs in discussions with contract development and manufacturing organisations (CDMOs) and other scientific partners.

What are the safe handling procedures for companies working with HPAPIs?

Safety and quality protocols from the handling perspective, expert review from toxicologists and EHS teams, and developing a containment strategy with a measure of exposure are the key factors that need to be worked on between CDMOs and customers. Robust, sensitive analytical methods are critical for CDMOs for the detection and cleaning strategy. The continuous learning programmes include risk assessment, defining process streams, identifying required isolation units, and focused employee training on potent work streams, ensuring an organisation’s productive, safe, and quality environment in handling HPAPIs. It’s a collaborative approach from safety, engineering, toxicology, and operations to have the most robust potent compound safety.

What training is required for employees to handle HPAPIs safely?

After identifying the potency or biological activity level of the HPAPIs, companies must establish appropriate safety handling procedures with safety and quality teams for each HPAPIs.”

After identifying the potency or biological activity level of the HPAPIs, companies must establish appropriate safety handling procedures with safety and quality teams for each HPAPIs. A hands-on training programme should be in place to ensure employees’ proper handling of the HPAPIs. Training and establishing a potent compound handling policy, gowning procedures, engineering control procedures, ways of communication in case of hazards, risk-based training on containment, weighing and transferring techniques, and use of personal protective equipment (PPE) and respirators are the critical training areas.

What are the key aspects of HPAPI development?

Managing highly potent cytotoxic compounds in early phases and at a late stage is a complex process. The facility, equipment-specific handling, experienced scientists, and EHS safety teams play a significant role in implementing the appropriate strategy and safeguarding people, facilities, and the environment. Achieving a solid track record of safe HPAPI manufacturing requires an in-depth understanding of the systems, compounds, and controls to minimise the risk and delays associated.

What is your prediction of the future HPAPI market?

Highly potent active pharmaceutical ingredients in the category of targeted therapies are growing at a healthy rate. Rapid growth in oncology and antibody-drug conjugate markets continues to drive the development of CDMOs for HPAPIs.

About the authors

Catherine Eckford is Editorial Assistant at European Pharmaceutical Review.

References

- Global high potency active pharmaceutical ingredient (HPAPI) market report 2022: A $34+ billion market in 2026 – long-term forecast to 2031. [internet] GlobeNewswire. Research and Markets. 2022. [cited 2023Feb]. Available from: https://www.globenewswire.com/en/news-release/2022/06/20/2465146/28124/en/Global-High-Potency-Active-Pharmaceutical-Ingredient-HPAPI-Market-Report-2022-A-34-Billion-Market-in-2026-Long-term-Forecast-to-2031.html

Related topics

Active Pharmaceutical Ingredient (API), Biopharmaceuticals, Drug Development, Drug Manufacturing, Drug Safety, Manufacturing, QA/QC, Research & Development (R&D), Therapeutics