Quo vadis, Laboratory Automation Education?

Posted: 7 April 2008 | Dr. Reinhold Schäfer, Professor of Databases, Laboratory Automation, and Artificial Intelligence Fachhochschule Wiesbaden – University of Applied Sciences | No comments yet

The increasing need for improved efficiency, precision and 24/7 operation imply more and more sophisticated measures in laboratory automation. This is true for a variety of fields – from pharmaceutical to food, agricultural, and the petrochemical industry, as well as forensics and medical diagnostics. Chemical and biological tests have to be supported by very small individual samples in medicine and forensics, up to continuous flow production with inline quality control in the chemical industry. A vast variety of physical, chemical, and biological methods need to be supported by experiment design and control, data acquisition and evaluation, documentation as well as simulation. Time constraints, high performance, extensive resource utilisation, and reproducibility of results demand a high degree of automation including unmanned operation. Global collaborations within multinational companies are the order of the day. Regulatory compliance with its diversity of validation processes increases the complexity of tasks. In addition, laboratory automation is no longer limited to R&D or production laboratories; it is now totally integrated into almost all production systems in a globalised enterprise. Adequate automation solutions always need the expertise of domain experts and automation specialists.

The increasing need for improved efficiency, precision and 24/7 operation imply more and more sophisticated measures in laboratory automation. This is true for a variety of fields – from pharmaceutical to food, agricultural, and the petrochemical industry, as well as forensics and medical diagnostics. Chemical and biological tests have to be supported by very small individual samples in medicine and forensics, up to continuous flow production with inline quality control in the chemical industry. A vast variety of physical, chemical, and biological methods need to be supported by experiment design and control, data acquisition and evaluation, documentation as well as simulation. Time constraints, high performance, extensive resource utilisation, and reproducibility of results demand a high degree of automation including unmanned operation. Global collaborations within multinational companies are the order of the day. Regulatory compliance with its diversity of validation processes increases the complexity of tasks. In addition, laboratory automation is no longer limited to R&D or production laboratories; it is now totally integrated into almost all production systems in a globalised enterprise. Adequate automation solutions always need the expertise of domain experts and automation specialists.

The increasing need for improved efficiency, precision and 24/7 operation imply more and more sophisticated measures in laboratory automation. This is true for a variety of fields – from pharmaceutical to food, agricultural, and the petrochemical industry, as well as forensics and medical diagnostics. Chemical and biological tests have to be supported by very small individual samples in medicine and forensics, up to continuous flow production with inline quality control in the chemical industry. A vast variety of physical, chemical, and biological methods need to be supported by experiment design and control, data acquisition and evaluation, documentation as well as simulation. Time constraints, high performance, extensive resource utilisation, and reproducibility of results demand a high degree of automation including unmanned operation. Global collaborations within multinational companies are the order of the day. Regulatory compliance with its diversity of validation processes increases the complexity of tasks. In addition, laboratory automation is no longer limited to R&D or production laboratories; it is now totally integrated into almost all production systems in a globalised enterprise. Adequate automation solutions always need the expertise of domain experts and automation specialists.

Profile of automation specialists

Given this background, the skill profile of an automation specialist becomes clear: he/she needs to be able to analyse the target of interest, develop solution alternatives with risk and cost/benefit analyses, orchestrate the implementation with validation tests and organise the introduction. A broad range of education is needed to comply with this skill profile: the automation specialist has to possess an adequate understanding of the scientific context, appreciation of the technological background – both for the instrumentation and the target’s environment, and, last but not least, superior knowledge to integrate the solution using informatics as a “glue”.

Laboratory automation education

Laboratory automation education consists of at least three major components: 1: The scientific methodology to solve the problem. 2: The adequate instruments. 3: Software to integrate the technical solution into the company’s environment. In the case of technology providers, broad knowledge also needs to be available to develop hardware and system software and integrate them. Consequently, the course program ideally should be composed of engineering, computer science, and fundamentals of science.

Such university programs for laboratory automation are rare. The Universities of Indiana (IUPUI) and Rostock, Germany, have implemented entire M.Sc. programs. Others like Keck Graduate Institute, Claremont, CA, and University of Applied Sciences Wiesbaden, Germany, have embedded laboratory automation education in their Biosciences or Computer Science Master and Diploma programs. Dr.Ing. degrees may be attained at the Center of Life Sciences Automation, University Rostock (celisca). All institutions offer courses in Mathematics and Computer Sciences. Depending on the institute’s focus, Life Sciences, Engineering and Economics courses exist. Manifold contacts between university institutes and industry are in place. Industrial projects are implemented at the institute – in some cases in collaborative project groups.

Technology providers offer a variety of courses dedicated to their automation solutions. Due to budgetary restrictions, universities are seldom able to participate – even if the knowledge transfer would be essential. At the same time, scientists and engineers from industry rarely come back to the universities for sabbaticals or collaborative projects – an option which might be beneficial for both parties.

As a non-profit organisation, the “Association for Laboratory Automation (ALA)” is dedicated to education in this field. Automation methodology and solutions are presented at LabAutomation Conferences1. The next conference will consist of five specific application area tracks: Detection and separation; micro- and nanotechnology; high throughput technologies; informatics; new frontiers for Lab Automation. A series of short courses, a poster program and an exhibition will complement the conference program.

Increase synergies between industry and academia

Automation specialists are urgently needed in many industries. Today, companies have to invest heavily in the additional training of university graduates to prepare them for their jobs. Why should industry and universities not cooperate in the field of education? The author is aware of the controversies: Industry complains that university education is often too theoretical. The universities, on the other hand, are afraid that joint educational activities might concentrate too much on project implementations, not giving enough room to training sustainable knowledge on methods utilisation. These fears can be overcome; the author has experienced this in several successful projects!

The following rules should be followed:

Create sustainable knowledge via practical experience.

It has been proven in many areas that practical experience intensifies learning dramatically. Unfortunately, in many institutions it is difficult to finance sophisticated instrumentation for the practical training of students. That is why university institutes and companies should jointly define the course content and the equipment needed. The universities provide premises, companies sponsor the equipment. Alternately, public funds may be raised. Course material may be developed in a joint effort.

In case enough training facilities are available within companies, students could also utilise them in such cooperations.

Intensify projects between industry and universities.

Research and applied research cooperations between industry and universities are already common. They bring substantial know-how transfer in both directions. Students experience major advantages when working in such projects.

Utilise existing electronic material.

Today, a wide variety of electronic course material is available in companies. It may intensify students’ knowledge if it is made accessible to them. Material that is not yet available may be developed in joint efforts between companies and universities.

Support internships and semesters abroad.

Universities should enhance their curricula not only by encouraging semesters abroad but also by offering credit internships for special courses.

Bring industrial experts into universities.

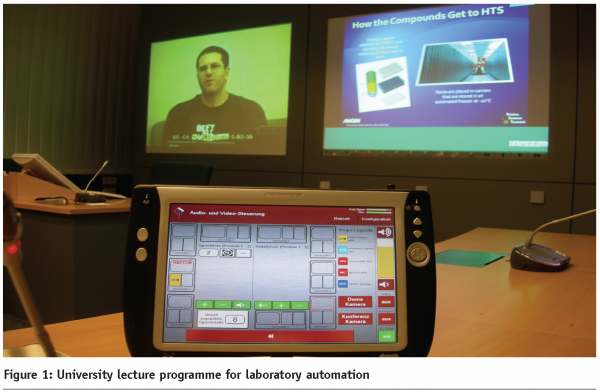

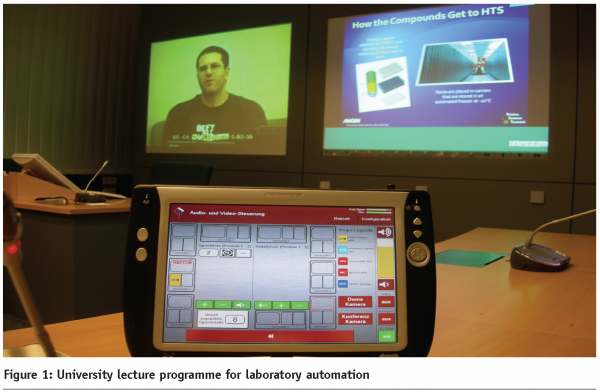

Laboratory automation is developing very rapidly. Experts are spread all over the world. Nevertheless, it would be beneficial to introduce students to them early. Distances today can be easily bridged by utilising modern video conferencing and desktop sharing technologies. Universities are introducing such technologies now (see Figure 1). The author experienced such remote presentations and lectures in a “Series of Laboratory Automation Lectures” at his university which was very successful. Ten companies provided lectures. Students were able to interact with the remote presenters via video and audio. From a content and technology point of view it was a big success.

Share laboratory automation courses.

Sharing expertise among different universities will help to enhance laboratory automation education. The University of Applied Sciences Wiesbaden, University Rostock and IUPUI, Indianapolis, offered such a collaborative course with great success. At all locations, video conferencing equipment and shared desktop facilities were used, so that all participants were able to interact.

Perform collaborative projects.

The most intense form of interaction is the implementation of collaborative projects. The internet and video conferencing help to realise these. Many different application scenarios can be supported, such as distributed applications, remote instrument control, or the utilisation of a remote expert’s opinion. This scenario was also tested with students from our institution and IUPUI with a lab on a chip platform simulator.

Conclusion

The author is convinced that laboratory automation education will be enhanced in the next few years, utilising modern collaboration technologies. Financial support from companies to set up video conferencing facilities and instrument pools for enhanced practical training and projects will help dramatically to increase students’ know-how in laboratory automation. In addition, universities and industry should increase their research cooperation for the mutual benefit of all partners. Non-profit organisations like the “Association for Laboratory Automation (ALA)” may catalyze these activities.

References

- LabAutomation08, Palm Springs, CA, USA, Jan 26-30, 2008

Dr. Reinhold Schäfer

Professor of Databases, Laboratory Automation, and Artificial Intelligence Fachhochschule Wiesbaden – University of Applied Sciences

Dr. Reinhold Schäfer is Professor at the University of Applied Sciences Wiesbaden, Wiesbaden, Germany. He studied Physics at the Johannes Gutenberg University Mainz, Germany, and received his Doctor degree in Biophysics also in Mainz. Between 1973 and 1989 he worked for the Pharmaceutical Industry. His last position was Corporate Manager, Scientific Information Systems for a globally operating company. At the University of Applied Sciences Wiesbaden he is teaching Database Systems, Artificial Intelligence, and Laboratory Automation. In his Wiesbaden Computer Integrated Laboratory (WICIL) he has been working since 1989 on software for laboratory automation. Main fields include; scheduling, instrument adaptation and control in plug-and-play mode, expert systems for error recovery, graphical user interfaces for procedure management and workbench supervision, identification problems, and the XML modeling of analytical instruments. He recently implemented a Virtual Classroom at his University. Dr. Schäfer is the 2007 President of the Association for Laboratory Automation. He is cooperating with many companies and research institutions in Europe and the US. He has published in journals, presented his work at international conferences, and is teaching short courses about LIMS and laboratory automation.