The new KORSCH X 3 tablet press: maximising mid-range production

Posted: 1 September 2020 | Korsch | No comments yet

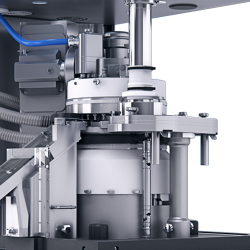

The X 3 is a breakthrough in the small-scale and mid-range tablet press market segment and the latest advancement from KORSCH.

The X 3 is a breakthrough in the small-scale and mid-range tablet press market segment, designed from the ground up to incorporate the latest KORSCH advancements. The X 3 is a single-sided rotary tablet press that redefines flexible technology with a new approach to architectural and ergonomic design elements, which were previously available only on larger machines. The X 3 is smarter and Pharma 4.0 ready, which permits a deeper understanding of what is happening in the compression suite. This is the basis to optimise both the process and the manner in which the process is executed by the operations team to obtain maximum product quality.

Flexibility

Efficiency

Related topics

Drug Manufacturing, Formulation, Lab Equipment, Manufacturing, Production