Taking the difficulty out of API process filtration

Posted: 26 April 2019 | Amazon Filters Ltd. | No comments yet

Amazon Filters has selected the Making Pharmaceuticals Exhibition & Conference 2019 to showcase its latest filter housings and microfiltration filter cartridges, which are used in the manufacture of Active Pharmaceutical Ingredients (API) and are the essential components when creating pharmaceutical products.

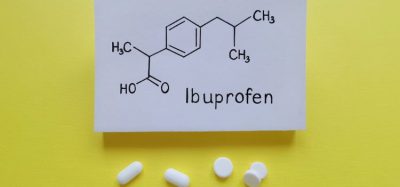

It is critical that APIs have been manufactured to the highest possible quality in order to make sure that the final product meets specification. Amazon Filters is highly experienced in supplying productive solutions for the different parts of the API production process, whether it is the initial filtration of raw chemicals and solvents, the purification of the compound with the use of carbon or the fine quality control of the finished product.

A typical API manufacturing process involves use of highly corrosive chemicals such as concentrated

To solve this challenge, Amazon Filters has developed two proprietary filter housings that can cope with these difficult applications. One of the filter housings uses Tantalum metal deposition and the second has been manufactured with an all PTFE construction. Both of these specialist filtration housings have demonstrated in multiple API manufacturing process applications a significant resistance to corrosive chemical damage.

For more aggressive API manufacturing processes that involve concentrated acids or a high temperature, the Amazon Filter range of SupaPore microfiltration cartridges can be supplied in either Halar or PTFE materials. These filters are available with ratings as fine as 0.1µm and up to over 100µm, so are suitable for all particle control applications.

Drawing upon their in-depth knowledge and long experience of pharmaceutical processes and applications, technical staff will be available on Making Pharmaceuticals** Stand 407 to offer advice on which filter and filtration housing is most compatible with the mixture of different chemicals and solvents used in your API manufacturing process.

Amazon Filters are fully conversant with the US FDA and European regulatory requirements for the design and use of filtration products in key pharmaceutical production areas including API manufacturing, sterile products, support utilities as well as the manufacture of creams and ointments.

For further information on effective solutions for API process filtration please contact Amazon Filters on +44-1276-670600 / [email protected].

Amazon Filters Ltd. design and manufacture an extensive range of liquid and gas filtration systems, providing one of the widest selections of filter vessels, along with depth and pleated cartridges for use throughout the food & beverage industry. As a leading manufacturer of filtration systems, Amazon Filters can offer a solution to meet all filtration requirements. Amazons’ filters are manufactured in clean room conditions and all products come with detailed Product Validation Guides and Technical Support documentation. To view a video on Amazon Filters design and manufacture capabilities please visit www.youtube.com/watch?v=DG9S6SLDgM4

Related topics

Active Pharmaceutical Ingredient (API), Biopharmaceuticals, Drug Manufacturing, Manufacturing, Production, QA/QC, Technology