Raw material identity verification in the pharmaceutical industry

Posted: 13 June 2013 | Dr. Bülent Üstün (Merck Sharp & Dohme) | 4 comments

Inspection of incoming raw materials is an essential step in the pharmaceutical industry to verify that the correct raw material which meets the quality specifications has been received. It will not only help to ensure that the final product is of best quality and minimise wasted time, material costs and delayed shipment if specifications are not being met, but also maintain safety. The presence of an incorrect material in a manufacturing process could compromise safety. For this reason, at least one test to verify the identity of incoming raw materials should be conducted before use (as required by regulatory authorities).

Sampling strategy

The inspection of incoming raw materials starts with checking packages for damage and correct labels. After visual inspection, incoming raw materials in general are moved to a sampling booth (safe sampling area) to avoid (cross-) contamination and operator exposure. Once in the sampling booth, the container or sack is opened and a sample is extracted. After sampling, the containers or sacks must be properly and securely closed before leaving the sampling booth to prevent contamination, shelf life and stability issues.

In the pharmaceutical industry, two sampling strategies are typically used for raw material identity verification purposes, namely:

- Sampling of each container, N samples per lot

- Sampling square root of the lot size plus one (√N+1) containers where N is the number of containers per lot.

After sampling, the samples will be sent to the laboratory for identity verification analysis. The raw materials will be placed in quarantine until laboratory analyses confirm the identity of the material. Once released, the raw materials are available for production.

Although use of the second sampling strategy (√N+1) described above leads to a significant reduction in the number of samples, an increase in the number of containers per lot will lead to an increase of samples. This will not only cause an increase in workload, but will also increase cost and lead-time. As the number of samples increases, the number of identity tests per lot will also increase, which means that it takes more time to release. It can even lead to a production delay.

Efficient identity verification of incoming raw materials

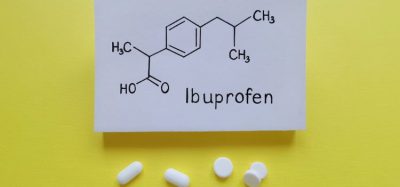

Given the workload and lead time, efficiency gain can be achieved by replacing commonly used, time consuming and labour intensive analytical techniques for identification such as HPLC (high performance liquid chromatography), TLC (thin layer chromatography), GC (gas chromatography) and wet chemical methods by fast and easy to use spectroscopic methods such as NIR (Near Infrared), Mid-IR (Mid InfraRed) and Raman. Although this will result in increased laboratory efficiency and cost reduction, sampling is still required. Another more efficient means is to move raw material identity testing out of the laboratory and into the warehouse. This leads to avoidance of laboratory analyses, cost reduction, lead-time reduction and inventory reduction. Nowadays, a wide selection of spectroscopy devices is available on the market which can be used in the warehouse to verify the identity of raw materials.

Identification versus verification

Raw material identity testing by spectroscopic techniques like NIR, IR and Raman is performed by comparing a measured spectrum with a library of reference spectra. Raw material identity testing can be classified into raw material identification and raw material identity verification. Raw material identification is the process of determining the highest spectral similarity between the measured spectrum of an unknown material against all spectra in a reference library. The library material that gives the highest spectral similarity3 is then identified as the most likely identity of the unknown material. Raw material identity verification is the process of accepting or rejecting (Pass or Fail) the ‘known’ identity of the incoming material claimed by the vendor. The measured spectrum of the incoming material is compared to the reference library spectrum (or spectra) of that material to verify its identity. If the match is good enough, i.e. above a threshold, the identity claim is accepted (Pass). The fundamental difference between identification and verification is the number of decision alternatives. In identification, the number of decision alternatives is equal to the number of raw materials in the library, whereas in verification there are only two choices, Pass or Fail. In the pharmaceutical industry, identity testing of incoming raw materials is classified as identity verification.

Spectral library development

The identity claim is only accepted if the spectral similarity between measured spectrum and reference library spectrum is above a threshold. A high threshold makes it difficult to accept incorrect raw materials, but with the risk of falsely rejecting correct materials. Conversely, a low threshold value enables correct materials to be accepted consistently, but with the risk of accepting incorrect raw materials. For this reason, it is very important to establish a reliable threshold during the development of spectral libraries. The development of a spectral library starts with the collection of reference spectra. Although fundamentally a single spectrum of a material may be sufficient to develop a valid spectral library in practice, it is recommended to collect spectra from different batches to build up a representative set of reference spectra and to elucidate possible batch-to-batch variations. If there is a batch-to-batch variability, it will help to establish a reliable threshold value and overcomes false acceptance or false rejection of a material. Otherwise, it will serve as a proof that there is no batch-to-batch variability, which is also a measure of reliability of the threshold value. Another point of discussion is whether a library should be vendor specific yes or no. Some raw materials show considerable vendor-to-vendor variations like quality, purity, particle size, humidity, etc. These differences may result in spectral differences, which can decrease the threshold value and thus the reliability of the library. To avoid this, it is recommended to build a vendor specific spectral library, for example, a benzoic acid library for vendor A and vendor B.

Validation

Once a spectral library has been developed, it must be validated to ensure performance and reliability. Validation of spectral libraries for identity verification purposes are usually performed by determining its false-negative and false-positive rates. The false-negative rate is the proportion of all positive raw materials that are falsely identified as negative (fail). The falsenegative rate of a spectral library can be determined by measuring the spectra of batches that were not used in the development of the spectral reference library. The falsepositive rate is the proportion of all negative raw materials that are falsely identified as positive (pass). The false-positive rate can be determined by cross-checking spectra against other libraries and also that spectra from other libraries do not match. Ideally, a valid and reliable spectral library would have a zero false-negative and a zero false-positive rate. A false-negative rate different from zero indicates that the reference library is not representative. The reason for this could be that the batch-to-batch variation is not included in the reference library, which results into an incorrect (high) threshold. A falsepositive rate different from zero indicates that raw materials are not properly discriminated due to spectral similarity. This can be for two reasons: (1) the same raw material and quality, but different vendor (2) different raw material but same or substantially equal spectra. In the case of (1), it can be utilised as valid library. In case of situation (2), the library is invalid and cannot be used without additional research.

In order to develop a valid and reliable spectral library, it is essential to have a welldocumented protocol stating how library development and validation will be conducted, including the number of batches and spectra required for library building and validation.

Summary

Raw material identity verification is a daily activity in the pharmaceutical industry, which is a costly and time consuming process. Simplification of sampling strategy and especially simplification of the analytical method can significantly reduce analysis cycle time and cost. However, the highest efficiency and cost reduction can be achieved by moving raw material identity testing out of the labora – tory and into the warehouse. The resulting benefits are:

- No need for expensive and time consuming laboratory analysis

- Workload reduction

- Cost reduction

- Lead-time reduction

- Inventory reduction

- Further efficiency can be gained by measuring through the original package without sampling

- No need for sampling

- Avoids operator exposure

- No risk of cross contamination

- No shelf life issues

- More consistent quality of raw material delivered.

References

- FDA Code of Federal Regulations 21CFR211.84

- www.accessdata.fda.gov/…ICH Q7 Good manufacturing practice for active pharmaceutical ingredients

- P.S. Thenkabail, P. GangadharaRao, T.W. Biggs, M. Krishna, and H. Turral, Spectral Matching Tech – niques to Determine Historical Land-use/Landcover (LULC) and Irrigated Areas Using Timeseries 0.1-degree AVHRR Pathfinder Datasets, Photogrammetric Engineering & Remote Sensing, 2007,Vol. 73, No. 9, pp. 1029–1040

Biography

Dr. Bülent Üstün is a senior scientist at Merck Sharp & Dohme, Oss, The Netherlands. He received a PhD degree in Chemometrics from Radboud University of Nijmegen, The Netherlands. During his PhD in the group of Professor Lutgarde Buydens, he focused on the development of chemometric algorithms for both qualitative and quantitative analysis. He was mainly interested in the area of support vector machines. After receiving his PhD in Chemometrics (2008), he moved into the pharmaceutical industry and joined the Analytical Science group at Merck Sharp & Dohme. He currently focuses on the development and implementation of spectroscopic methods to increase the product quality and the understanding of processes and to increase cost efficiency.

If in a monograph of a raw material there are mentioned 2 First Identification tests, both must be performed or only one is considered to be sufficient?

How many times is it require to perform ID test for verifying method?

We are the well known Indenting house in Bangladesh of Pharmaceuticals & Food Industry. Our company name is Multinational General Trading (MGT). We are interested to work with European pharmaceutical raw materials manufacturers in Bangladesh market. Please contact with us to marketing your products in Bangladesh market by potential partner.

We are a Nigerian registered company and a licensed exporter with the Nigerian Export Promotion Council (NEPC).

We are exporters and intermediaries of Agricultural products and Solid minerals: Garcinia Kola (bitter kola), Ginger, Garlic, Charcoal, Sesame seeds, Gold etc and would like to supply you any of the above as raw materials.

hoping to hear from you.

thank you.

[email protected]