In-air microfluidics produces 3D printed structures of living cells

Posted: 1 February 2018 | Dr Zara Kassam (European Pharmaceutical Review) | No comments yet

Scientists have succeeded in printing 3D structures with living cells, this enables the production of micro building blocks that are viable and can be used for repairing damaged tissue…

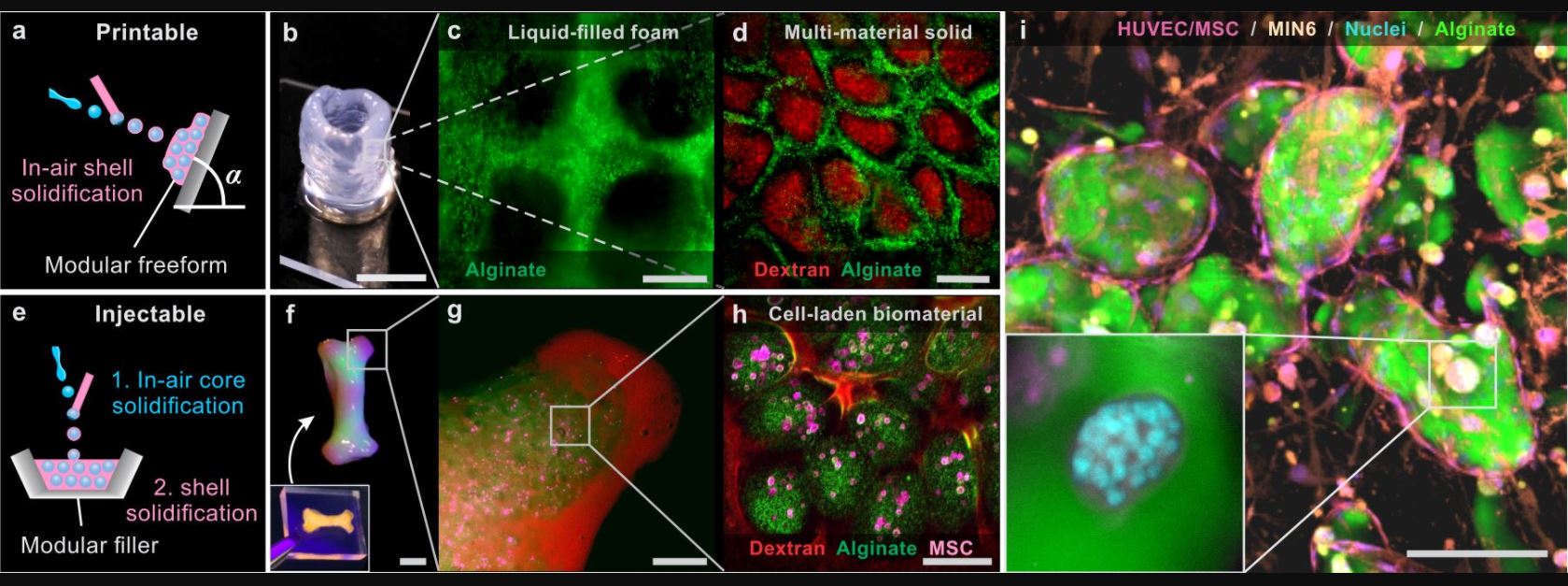

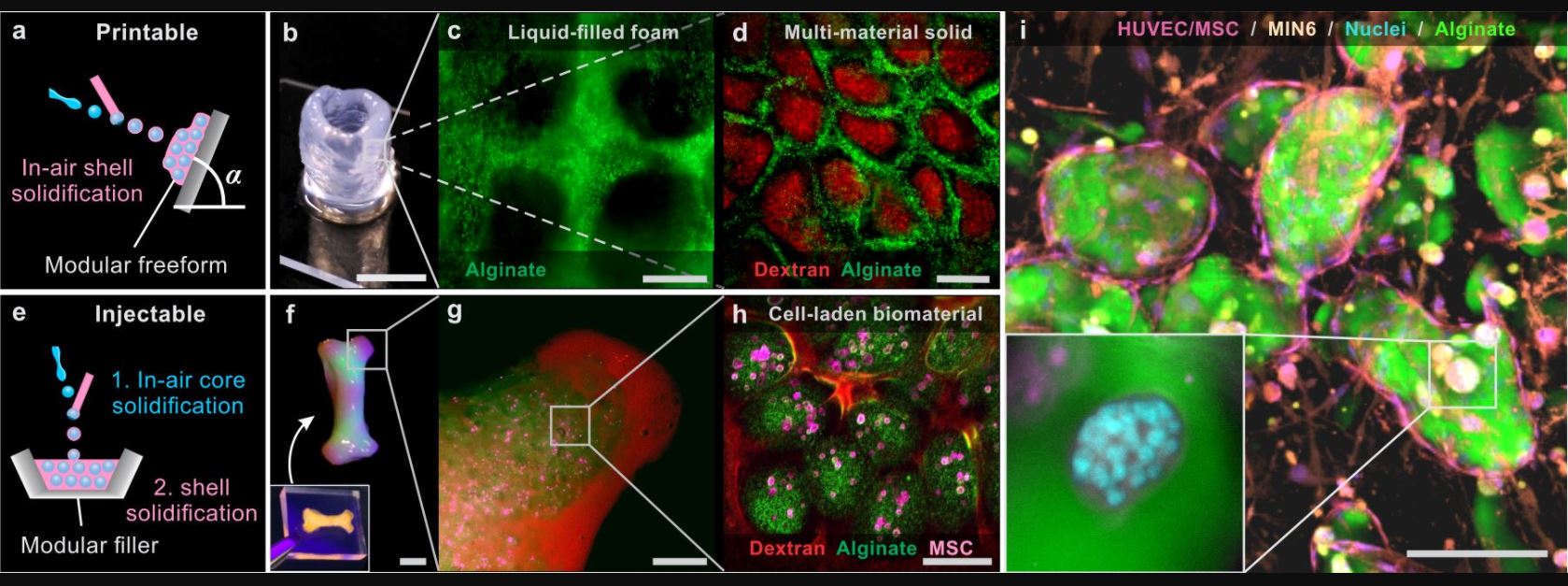

Using a new technique they call ‘in-air microfluidics’, scientists succeed in printing 3D structures with living cells. This special technique enables the fast and ‘on-the-fly’ production of micro building blocks that are viable and can be used for repairing damaged tissue.

Microfluidics is all about manipulating tiny drops of fluid with sizes between a micrometre and a millimetre. Most often, chips with tiny fluidic channels, reactors and other components are used for this: lab-on-a-chip systems. Although these chips offer a broad range of possibilities, from producing emulsions for example – droplets carrying another substance – the speed at which droplets leave the chip is typically in the microliter per minute range. For clinical and industrial applications, this is not fast enough: filling a volume of a cubic centimetre would take about 1000 minutes or 17 hours. The technique that is presented now, does this in a couple of minutes.

Can we reach these higher speeds by not manipulating the fluids in microchannels, but in the air instead? This was one of the questions the researchers wanted to answer. And indeed it was possible, by using two ‘jets’ of fluid. From one jet, droplets are shot at the other jet. Creating the jets is relatively simple, and they move 100 to 1000 times faster than droplets from a microchip. Speed is not the only advantage. By choosing jets containing different types of fluids that react, the ‘collision’ results in new materials. Smart combinations of fluids will result in solid and printable building blocks in one single step.

In this way, it is possible to capture a living cell inside the printable material. The resulting bio building blocks are printed in a 3D structure that looks like a sponge, filled with cells and fluid. These 3D modular biomaterials have an internal structure that is quite similar to that of natural tissue. Many 3D printing techniques are based on using heat or UV light: both would damage living cells. The new microfluidic approach is, therefore, a promising technique in tissue engineering, in which damaged tissue is repaired by using cultured cell material of the patient.

The paper ‘In-air microfluidics enables rapid fabrication of emulsion, suspension and 3D modular (bio)materials’, by Claas Willem Visser, Tom Kamperman, Lisanne Karbaat, Detlef Lohse and Marcel Karperien, has been published in Science Advances, of the American Association for the Advancement of Sciences (AAAS).

Related topics

Related organisations

Related people

Claas Willem Visser, Detlef Lohse, Marcel Karperien, Prof Marcel Karperien, Tom Kamperman