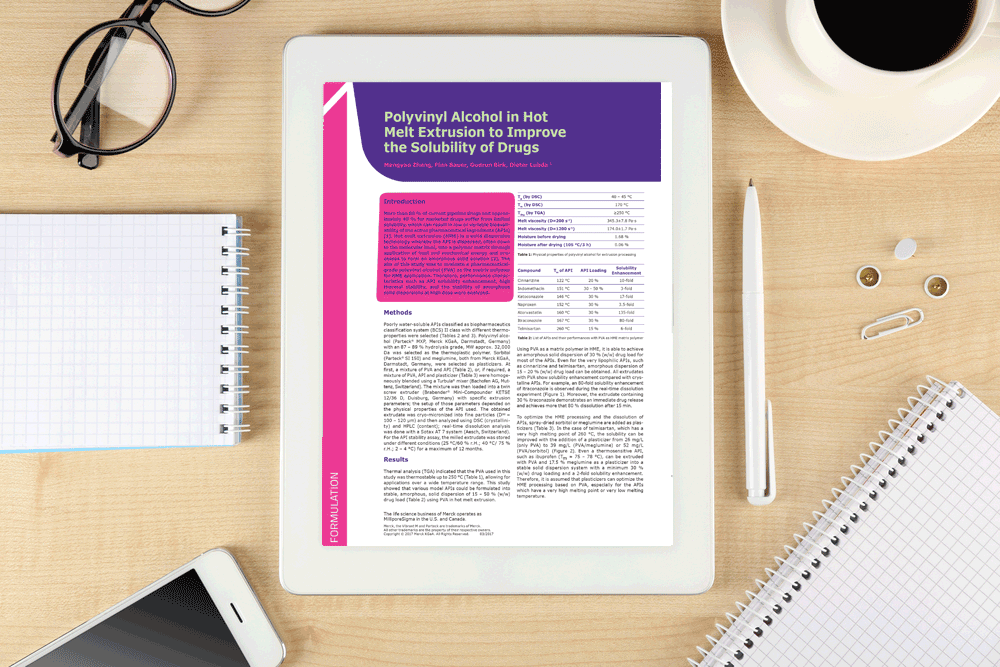

Poster: Polyvinyl alcohol in hot melt extrusion to improve the solubility of drugs

Posted: 4 July 2017 | Merck | No comments yet

This poster evaluates a pharmaceutical grade polyvinyl alcohol (PVA) as the matrix polymer for HME application…

More than 80 % of current pipeline drugs and approximately 40 % for marketed drugs suffer from limited solubility, which can result in low or variable bioavailability of the active pharmaceutical ingredients (APIs). Hot melt extrusion (HME) is a solid dispersion technology whereby the API is dispersed, often down to the molecular level, into a polymer matrix through application of heat and mechanical energy and processes to form an amorphous solid solution. The aim of this study was to evaluate a pharmaceutical grade polyvinyl alcohol (PVA) as the matrix polymer for HME application. Therefore, performance characteristics such as API solubility enhancement, high thermal stability, and the stability of amorphous solid dispersions at high dose were analyzed.

The life science business of Merck KGaA, Darmstadt, Germany operates as MilliporeSigma in the U.S. and Canada.

This poster is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here