Challenges and innovations shaping the bioprocessing industry

Posted: 17 December 2021 | Robert Newman (FUJIFILM Irvine Scientific), Tom Fletcher (FUJIFILM Irvine Scientific) | No comments yet

In this article, Robert Newman and Tom Fletcher explore how the bioprocessing industry has changed in the last 50 years and where the future may lead…

Looking back at the last 50 years of the bioprocessing industry

The last 50 years has been transformational for the bioprocessing industry. Now, it is faced with even more pressing challenges, such as reducing the costs of development and commercialisation of therapies to make them more accessible to patients. High-throughput systems are needed to meet the growing demands and the increasingly complex regulatory requirements; with machine learning and high-tech driving this innovation further forward. In this article, we look back at how the industry has evolved, and how cutting-edge technological development and collaboration is accelerating further revolutionary change.

Celebrating achievements and milestones, and looking ahead

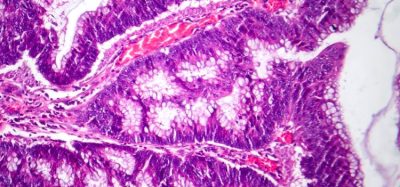

The bioprocessing industry has experienced tremendous change over the last 50 years, overcoming many initial challenges to enable increased efficiency and productivity across the developmental and manufacturing stages. These efforts have been particularly focused to elicit major advancements for cell lines and culture media used for the production of therapeutics. Initially, bioprocessing relied heavily on hybridoma cells to produce antibodies and blood sera as cell culture supplements, with not many alternatives available. There were many issues associated with hybridoma cells, especially the immunogenicity of the antibodies they produced, which induced immune responses in humans and reduced therapeutic potential. Moreover, antibodies were harvested from various animals which were used in some cases as live bioreactors, limiting yields whilst also generating high variability rates. Reducing this variability in bioprocessing has been critical to the industry’s progression.

High quality cell culture media underpin successful and high-yielding cultures needed for therapeutics production, with significant progress achieved to optimise these media to increase performance and minimise risk of contamination. A big step forward for the industry was the introduction of serum-free cell culture media, minimising variability in cell growth as well as the risk of infection by serum-borne adventitious agents. The culture media evolved further to remove serum completely from the formulation and introduced media free of any animal components; particularly challenging to achieve as serum proteins were a critical component at the time. Eventually, fully chemically-defined media replaced undefined media, with FUJIFILM Irvine Scientific introducing the first commercially available chemically-defined cell culture media for a variety of cell types. These media provide more control and consistency compared to media that contain undefined components or serum, which can impair cell expansion or differentiation.

In comparison to the current regulatory environment surrounding the bioproduction industry, in the initial stages of its establishment the development and commercialisation of cell and gene therapy products were less defined with fewer and less stringent regulations in place. Many earlier clinical studies used non-GMP and/or non-graded raw materials of biological origin without all the testing certifications and quality control measures which are required or expected by regulators today. These materials will require substitution to meet the current regulatory standards. Raw materials today must be traceable and fully qualified to ensure safety of the final product, and the entire development process is surrounded by appropriate risk mitigating activities to meet the required quality and safety standards. It’s becoming increasingly important for manufacturers to select qualified and knowledgeable suppliers who can provide high-quality materials, such as cell culture media, and assist with regulatory submissions to obtain approvals. Chemically-defined media are now considered the gold standard by regulatory authorities due to the minimised risk of adventitious agents and reduced variability resulting in higher quality end products.

Harnessing automation and machine learning, researchers’ gain the ability to closely analyse all-encompassing processes and generate detailed information to improve yield and quality”

As discussed, cell culture is a critical component to effective bioprocessing; with high-performing media formulations key to achieving improved efficiencies, higher productivity levels and quality protein products. In parallel, industry processes have also evolved to increase efficiency, resulting in higher outputs than ever before. With the rise of automation and intelligence technology, these processes can now be closely monitored and adapted; the analysis fed into process improvement to further increase yields and quality. This feedback mechanism evidences the constant evolution to meet needs.

High throughput technology (HTT) has become critical to accelerate process development, reduce timelines and overall cost, and for faster outputs which, when combined with optimised chemically-defined culture media, enables continuous bioprocessing. Similarly, the expanding use of single-use technology (SUT) accelerates this change. SUT has been the dominant trend in bioprocessing over recent years, due to numerous advantages over traditionally-used stainless steel or glass components, including minimised cross-contamination and easier maintenance. However, key considerations, such as cost and sustainability of SUT will need to be addressed, to make its application more widespread and environmentally-conscious.

One of the current bottlenecks faced in the development of advanced therapies is reaching high cell densities for viral cell therapy vectors and the increased nutrient replenishment needs of high-performing cell cultures. High quality optimised cell culture media, specifically formulated for particular outcomes, will be key in achieving this. Additionally, necessary improvements to obtain universal media that can be used across small- and large-scale manufacturing, without the need to reformulate or adjust to the scale of operations, are key. In addition to optimised cell culture media, immortalised cell lines offer a solution to accelerate the development of advanced therapies by providing an indefinite source of cells. To achieve this, the process must be supported by continued data analysis and automation of the media formulation process.

Harnessing automation and machine learning, researchers’ gain the ability to closely analyse all-encompassing processes and generate detailed information to improve yield and quality, and to fast-track the route to patients. However, with the large amount of data being collected new challenges arise. Appropriate organisational and IT infrastructure must be put in place to capitalise on the abundance of information and to make appropriate data-driven adaptations. As a consequence, the move towards bioindustralisation must be supported by strong partnerships and collaborative networks.

The future of bioprocessing

The COVID-19 pandemic has introduced unparalleled challenges globally. In the face of a novel virus, the development of therapeutics and vaccines throughout 2020 is just one positive example of various organisations coming together to exchange knowledge and information to respond to pressing healthcare needs. To succeed in this increasingly demanding and complex industry, partners must work collaboratively. Co-operation will underpin the future of bioprocessing, including between manufacturers, suppliers, governments and regulators to harmonise international processes and regulations.

The bioprocessing industry continues to evidence its increasing involvement in the future of healthcare and potential to drive innovation in human medicine. Despite being a constantly evolving field, the industry’s ability to rapidly respond to urgent needs highlights its significance. The advances in cell culture and automation of workflows encompass decades of expertise, ultimately striving to bring ground-breaking therapies to patients sooner. However, the field requires the continued maintenance and strengthening of international and inter-industry collaboration to do so.

About the authors

Robert Newman is the Chief Scientific Officer of FUJIFILM Irvine Scientific and Tom Fletcher is R&D Director in Process Development at FUJIFILM Irvine Scientific.

Related topics

Biologics, Biopharmaceuticals, Bioprocessing, Bioproduction, Drug Manufacturing, Industry Insight, Proteins, Technology