The nitty gritty of biotherapeutics production

Posted: 19 December 2023 | Caroline Peachey (European Pharmaceutical Review) | 1 comment

Caroline Peachey chats with Mahesh Bhalgat, COO at Syngene International Limited about the role of new technology in biotherapeutics production.

Can you reflect a little on what’s happening from a technology standpoint in the bioproduction space?

Mahesh Bhalgat (MB): We are seeing continued emphasis on use of technology, as we’ve seen historically, but even more so now on titer and productivity. And that is now translating into evaluating productivity of the overall process. As a result, you’re starting to see a trend of not only looking at titer at the expression stage, but also combining titer with downstream purification yield to gauge the overall process efficiency.

There has been a change in mindset around cost considerations in productivity”

You can have a fantastic yield of 12 grams per litre in your fermentation process, but if you only recover around 60-65 percent in your downstream step you have wasted a lot of product. So, there has been a change in mindset around cost considerations in productivity. Companies are approaching it from all angles, such as fed-batch, intensified processes and other versions of high cell density processes.

Companies are trying to improve performance of their upstream and downstream processing and assessing the impact of, for example, reducing the number of processing steps, and redefining growth media etc to optimise yields.

Introducing such changes that provide better, more efficient processes, will still have to be accepted by the US Food and Drug Administration (FDA) or other regulators for commercial molecules. Use of technology approaches to understand and model the design space is what will help in the regulatory approval cycle. Dramatic changes in approach and technology models will require proper scrutiny to establish they are financially beneficial.

The other component that I think is important is the cell lines. Media costs today are still high — and the cost of the consumables (eg. bags) is a big part of it. Driving down any of these costly components will make a difference. Companies are therefore evaluating cell lines that can produce protein efficiently with less complex media and provide high protein yield through a focus on the feeding strategy.

On overall productivity there is the component of cell line opportunity; there is the media opportunity; and then the downstream opportunity. I’m now seeing much more of a push to bring all these aspects into the same conversation aided by technology based approaches and robust data sets.

Regulation of biotherapeutics: opportunity for evolution

One other dimension of opportunity is on the regulatory side. We have had guidelines that have been released over the last few years around biosimilars and around expectations for product quality, process characterisation, the importance of having your critical process parameters (CPPs) and your critical quality attributes (CQAs).

There were about 100+ biosimilars in the pipeline even before the pandemic”

I think there is more room for evolution. When you look at the number of biosimilars that are in development, there were about 100+ biosimilars in the pipeline even before the pandemic; while for new biologics, it is estimated that there are about 2500 in the pipeline.1 Add these to what’s been approved, these are still relatively smaller in number compared to small molecule drugs.

We need to get to that body of experience and body of evidence before we start to move more and more on the regulatory side on further reforms. It should be done in a much more tailored fashion. And I believe there is opportunity to use machine learning based approaches to strengthen the body of conclusions on biologic drugs and therefore use it to drive regulatory strategy.

Earlier you mentioned efforts to improve bioprocess efficiency, can you elaborate on some of the work in this area?

The way to bring efficiency is to look at continuous processing, single use and similar approaches”

MB: I think most important is to look at efficiency in your process, because you want better cycle times and greater productivity, so that each day, per reactor, or per column basis, you can get a high yield. You must look at things like continuous processing, scale up or scale down; does it make sense to do continuous processing in even a single unit operation? There are lots of ways to approach this and consider how to upgrade your process. The way to bring efficiency is to look at continuous processing, single use (which speeds up change over) and similar approaches.

Continuous processing requires implementation of process analytical technology (PAT). What are some of the challenges with implementing PAT, and how is it evolving?

MB: PAT is a great concept that has been around for a long time. We continue to talk about it in the context of a new framework because it hasn’t been implemented as widely as we could have. This is generally true of the industry and reflects our ability to adapt and change. It’s not straightforward to bring in all these components of change, due to the regulatory steps required for implementation.

There are opportunities to implement PAT on a practically everyday basis”

That said, PAT is based on the capability of equipment to do the kind of measurements that you want. I’ll give you an example. We’ve adopted a technology to measure protein concentration, which is far more reliable than what we were doing before and is done inline. This is a step in the direction of implementing PAT. There are such opportunities to implement PAT on a practically everyday basis. There is therefore enormous value in partnership between product manufacturers and technology developers to find what will be suitable for you.

We must continue to have that dialogue of saying, ‘I want to automate this analytical step. I don’t want an offline sample, or to wait until the end of my step; I want it along the way.’ Through the use of digital twin approaches, it is possible to predict the outcome of a batch based on the cell culture growth curves. This can avoid batch failures. As a different example, we can look at how water testing was being measured years ago: tests that were done offline are now inline and there is immediate stoppage of water if there are unusual results helping address a problem the moment it is detected. It is only when you start to ask the questions, that’s what drives the technology.

Finally, what excites you most about the biologics industry?

With more than 100+ ADCs under development, there are a lot of technology-based opportunities ongoing, even though we’ve already come a long way”

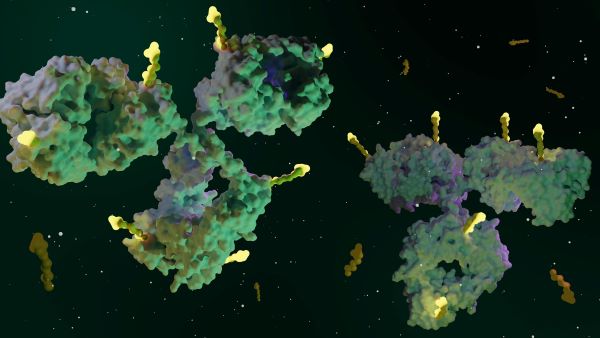

MB: The endless opportunities in the world of biologics. I’ve spent my whole career working in biologics; I actually worked on antibody drug conjugates (ADCs) for my PhD dissertation in the early 90’s. And only in the last few years have we seen nine new molecules (out of the total 13) approved as ADCs.2 With more than 100+ ADCs under development, there are a lot of technology-based opportunities ongoing, even though we’ve already come a long way.2

I think that there is more and more opportunity for us to improve the large molecule-based modalities with such examples.

What I’m hoping that we can leverage in this field of biologics is the opportunity to get a lot more targeted actions to things like bispecific antibodies or trispecific antibodies. That is the era to come and it looks even more exciting.

About the Interviewee

Mahesh Bhalgat is chief operating officer (COO) at Syngene International Limited, an integrated contract research, development, and manufacturing organisation. He spoke to Caroline Peachey during CPHI Barcelona.

References

- Biosimilars in the United States 2020–2024 [Internet]. 2020. [cited 2023Oct] Available from: https://www.iqvia.com/insights/the-iqvia-institute/reports-and-publications/reports/biosimilars-in-the-united-states-2020-2024

- FDA Approved Antibody-Drug Conjugates (ADCs) By 2023. [Internet] [cited 2023Oct] Available from: https://www.biochempeg.com/article/74.html

Related topics

Antibodies, Biologics, Biopharmaceuticals, Bioprocessing, Bioproduction, Continuous Manufacturing, Process Analytical Technologies (PAT), Regulation & Legislation, Research & Development (R&D)

Fascinating read on the evolution of biotherapeutics production. I’m curious about the balance between technological innovation and regulatory compliance. How do companies navigate the challenges of integrating new technologies, like PAT, in a highly regulated environment without compromising on efficiency and cost-effectiveness? Additionally, what role do you foresee for AI and machine learning in further advancing bioprocess efficiency and regulatory strategies?