Technique to stabilise freeze-dried cellular machinery could improve cell-free biotech

Posted: 3 March 2020 | Victoria Rees (European Pharmaceutical Review) | No comments yet

Researchers have discovered low-cost preservatives that enable freeze-dried cellular machinery to retain full activity when stored at room temperature for cell-free biotechnology.

Researchers have developed a new low-cost approach that improves cell-free biotechnology’s uses in biomanufacturing and portability for field applications.

…certain combinations of preservatives could enhance the protein-producing capacity of the cellular machinery nearly two-fold”

Cell-free protein synthesis (CFPS) is a biotechnology that harnesses active cellular machinery without the presence of living cells, allowing researchers to directly access and manipulate biochemical processes. This technology could potentially be used for on-demand biomanufacturing of biomaterials and therapeutics, but is currently cumbersome. The cellular machinery extracted for use in cell-free biotechnology contains biomolecules such as proteins and RNAs, which break down at warmer temperatures, greatly limiting the shelf life of the cellular machinery. Transporting it from one laboratory to another or taking it out of the lab for field applications requires refrigeration to maintain its activity; being tethered to the ‘cold chain’ is a fundamental limit to meeting cell-free biotechnology’s potential.

Scientists from California Polytechnic State University, US, have improved this technology. Inspired by storage optimisations of biological materials like cow’s milk, researchers have previously extended the shelf life of extracts by freeze-drying them, resulting in a product similar to powdered milk that can be stored at room temperature for extended time periods. However, freeze-dried cellular machinery cannot be stored for more than a few days without continual loss of activity. Now, the researchers have discovered low-cost preservatives that allow freeze-dried cellular machinery to retain full activity when stored at room temperature for up to two weeks.

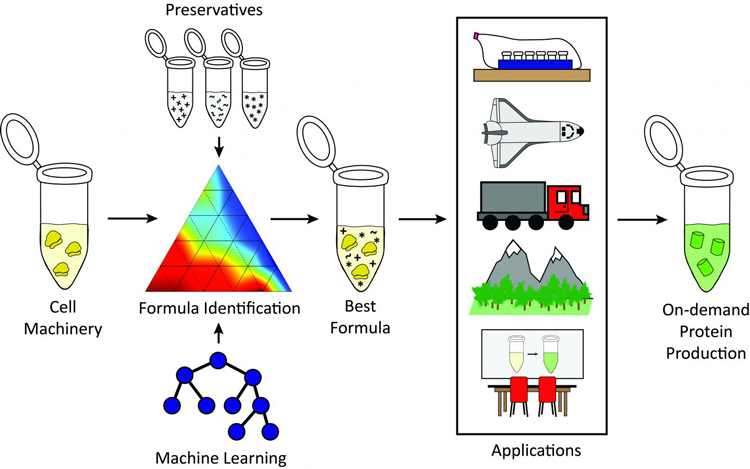

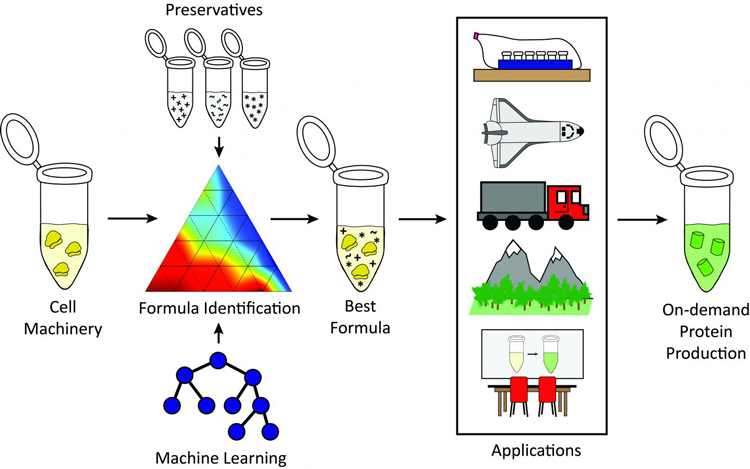

Preservative formulations have been discovered to improve storage of cell-free components at room temperature. Through the use of a machine learning algorithm, researchers can now identify preservatives that will enable their cell-free biotechnology applications to be viable outside of the lab for on-demand protein synthesis, point-of -care biosensing or therapeutic production and biochemical education (credit: Nicole Gregorio).

To accomplish this, the team pursued an interdisciplinary approach. They selected 10 preservatives with four distinct mechanisms of action and systematically identified the best performers, which were then tested in combinations of two or three. This approach allowed them to identify combinations of preservatives that could maintain the full productivity of the cellular machinery for two weeks at room temperature. They also discovered that certain combinations of preservatives could enhance the protein-producing capacity of the cellular machinery nearly two-fold.

The researchers demonstrated that the utility of any given preservative for stabilising biological materials is highly context dependent. To help overcome this limitation, their data was used to develop a machine learning algorithm to allow other users to identify preservative formulations that are ideal for their specific application of cell-free biotechnology.

The study was published in ACS Synthetic Biology.

Related topics

Biopharmaceuticals, Bioprocessing, Bioproduction, Drug Manufacturing, Ingredients, Manufacturing, Production, Proteins