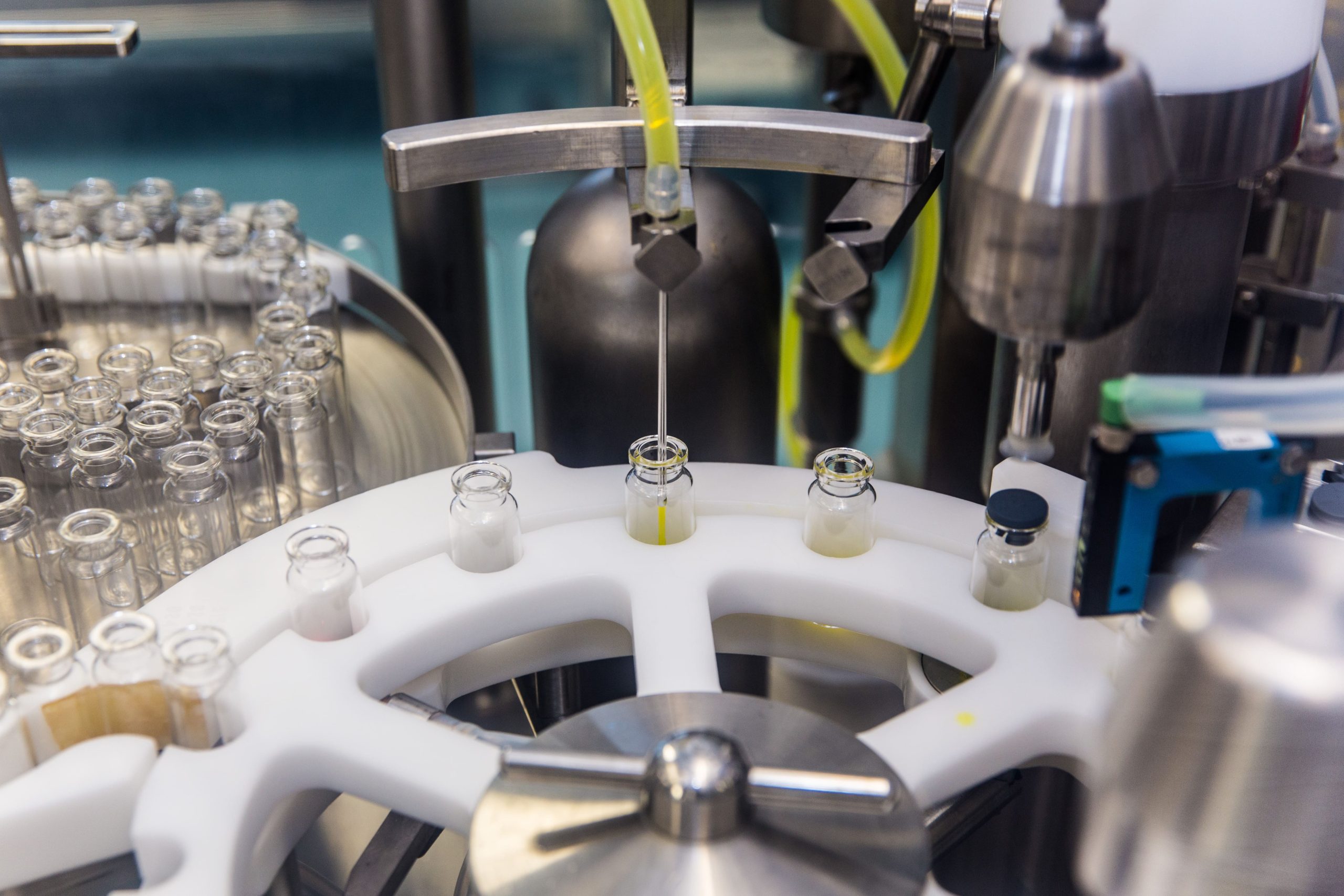

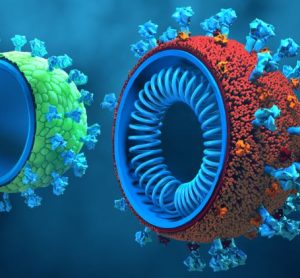

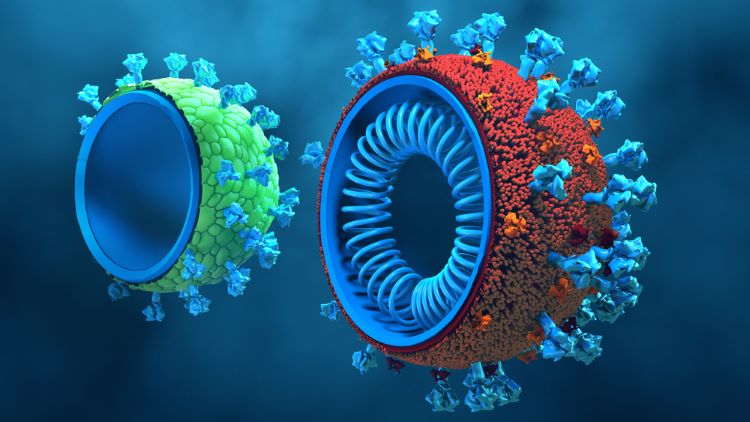

Simplified rAAV lysate purification for complex analytics of upstream samples

Bioprocess experts from Sartorius BIA Separations and BridgeBio Gene Therapy illustrate an approach with potential to expedite AAV upstream analytics and lower overall process development costs.