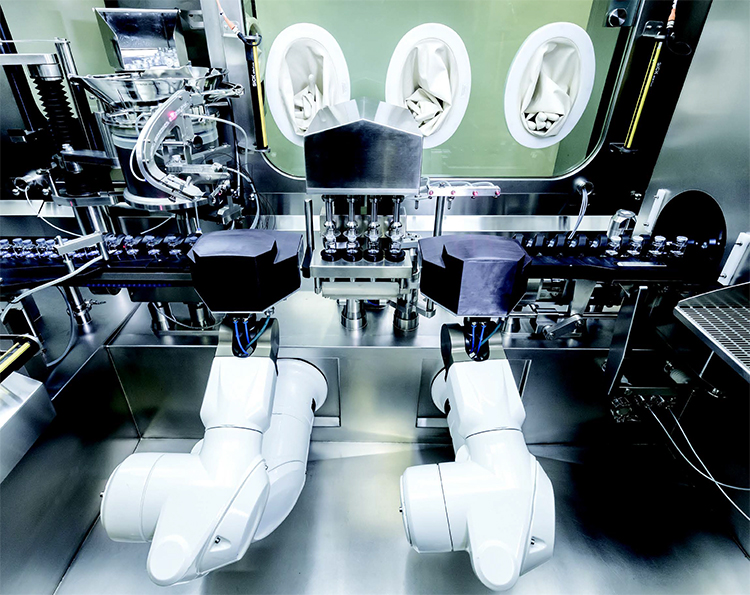

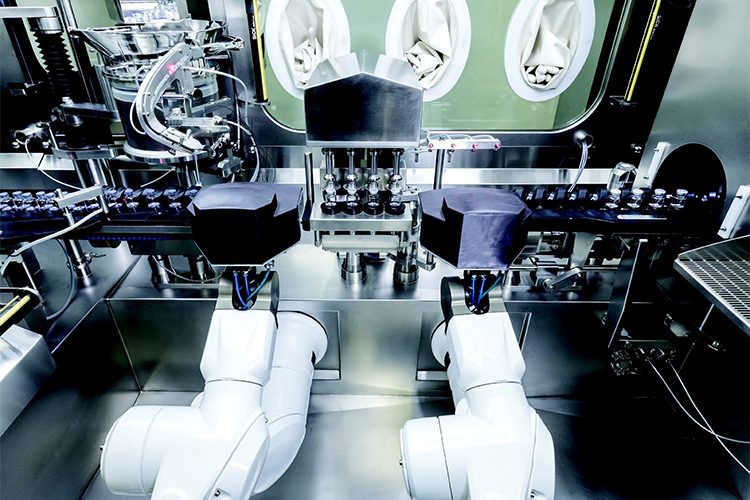

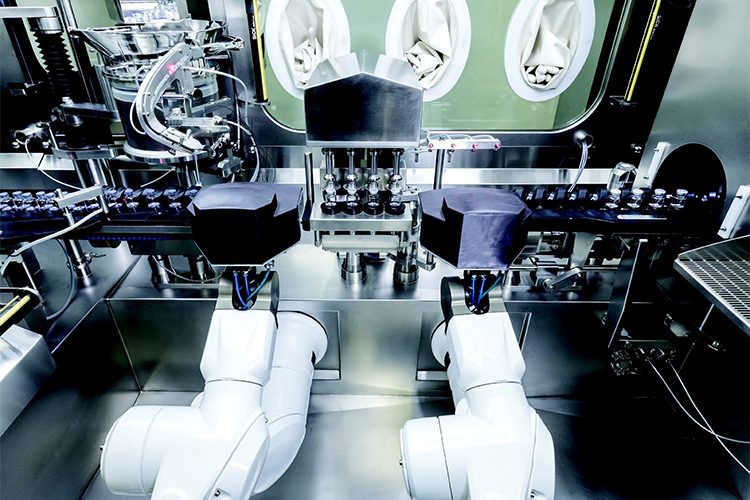

Steriline products and solutions: Robotic applications

As a single-source supplier of equipment solutions for the primary packaging of injectable drugs, Steriline develops, manufactures and supplies a comprehensive range of solutions, including both mechanical and robotic applications for the aseptic processing.

These applications are compatible with vials, ampoules, cartridges and syringes and can handle toxic or non-toxic products in both liquid and powder form.

Steriline’s complete lines include equipment spanning from washing machines, depyrogenation tunnels, filling and capping machines to external decontamination machines and barrier systems such as LAF, oRABS, cRABS and isolators.

Quality and sustainability

In 2015 Steriline has been certified ISO 9001:2008 and in 2018 ISO 9001:2015 and fulfills quality management system requirements, covering all production processes and organizational procedures to continuously improve customer satisfaction. Steriline is also compliant with cGMP, GAMP and 21CFRPart11 requirements. Moreover, Steriline places high relevance on protecting the environment and adopts sustainable business practices. The company complies with all applicable legislations regarding the environment and works economically and responsibly with resources.

Focus on robotic applications

In line with its pioneering role in the field of robotic applications for the aseptic processing market, Steriline’s efforts aim to widen the portfolio of robotic solutions to complement and further enhance the high quality, efficiency and safety standards ensured throughout its aseptic filling lines.

As of today, Steriline offer includes:

- Vial filling machines (RVFM)

- Vials capping machines (RVCM)

- External decontamination machines (EDM-RHP)

- Tray loader (RTL)

- Tub decontamination system (RTDS2)

- Nest filling machine (RNFM)

Robotic vial filling machines (RVFM)

- Designed for campaign production with containment technology

- Vial transport with anthropomorphic vaporized H2O2 compatible STÄUBLI robot

- Maximum of 12 open vials involved in filling and stoppering operations at the same time

throughout the machine (1 vial (RVFM1), 4 vials (RVFM2), 12 vials (RVFM5) - Minimum format parts and electronic adjustment of all parameters for different vial sizes

- Peristaltic and volumetric piston pump dosing systems

- Handling of single-use disposable system option

- 100 percent in-process control (= IPC) or statistical check weighing system directly under the filling

nozzles with feedback to dosing pumps - Net weight filling: no product waste fills up to target value for underfilled vials. No product

waste during the product path priming - Nitrogen flushing before and after filling

- Capping unit integration on the same monoblock.

- Zero reject philosophy: repeated operations for missing stopper detection

- Continuous monitoring of the viable and non-viable particles

- Compliance with cGMP, GAMP and 21CFR Part11 requirements

Robotic vial capping machines (RVCM)

- Designed for campaign production with containment technology

- Vial transport with anthropomorphic vaporized H2O2 compatible STÄUBLI robot

- Maximum of 12 vials involved in capping operations at the same time throughout the machine

(1 vial (RVCM1), 4 vials (RVCM2), 8 vials (RVCM5) - Minimum format parts and electronic adjustment of all parameters for different vial sizes

- One, two or four heads, depending on machine model

- Zero reject philosophy. Repeated operations for missing alu-cap detection

- Continuous monitoring of the viable and non-viable particles

- Compliance with cGMP, GAMP and 21CFR Part11 requirements

Robotic tub decontamination system (RTDS2)

- Designed to decontaminate tubs, before entering the de-liner station

- Compact (1928 * 1205 mm) and light weight

- Also available for trays

- Tub handling with anthropomorphic vaporized H2O2 compatible STÄUBLI robot

- Suitable to be installed in ISO8 environment

- 6 log reduction

Robotic nest filling machine (RNFM)

- Suitable for the applications under oRABS, cRABS and Isolator

- Combo line available for ready-to-use (= RTU) nested syringes, vials and cartridges

- Semi-automatic or manual de-bagger station.

- Automatic tub handling, for lid and liner removal with tyvek lid and insert removal, with

anthropomorphic vaporised H2O2 compatible STÄUBLI robot. Manual option available - Quick changeover and electronic adjustment of all parameters for different containers sizes

- Nest handling through filling and stoppering operations with anthropomorphic vaporized H2O2

compatible STÄUBLI robot - Volumetric and/or peristaltic pumps dosing system

- Single-use disposable systems available as option

- Statistical check weighing including feedback to dosing pumps

- Nitrogen gassing station

- Vacuum stoppering available as option

- Vacuum assisted filling suitable for viscous products

- Continuous monitoring of the viable and non-viable particles

- Compliance with cGMP, GAMP and 21CFR Part11 requirements