The benefits of mass spectrometry for expediting biologics to patients

Posted: 20 September 2023 | Ian Anderson (Lonza), Mostafa Zarei (Lonza), Qifeng Zhang (Lonza) | No comments yet

A key element of development for new molecular format biological products is to leverage the appropriate analytical tools to enhance product and process understanding throughout the development lifecycle. Here, Ian Anderson, Mostafa Zarei and Qifeng Zhang at Lonza highlight the benefits of using mass spectrometry technologies to accelerate and de-risk product and process development.

In recent years, the pharmaceutical industry has undergone a remarkable revolution, ushering in new and innovative products to address a wide range of unmet medical needs. Although this evolution has led to life-changing medications, it also calls on drug development and manufacturing experts to identify new, more efficient ways to deliver high‑quality products. Pharmaceutical development is driven by quality by design (QbD) – an approach recommended by regulatory agencies.1 QbD relies on a deep understanding of product quality attributes (PQAs) to define which subset of these become critical quality attributes (CQAs) by linking these to the quality target product profile (QTPP).

The presence of novel and increasingly complex molecules in today’s pipelines requires analytical methods with higher resolution, throughput and sensitivity. Development of multi-specific antibodies (msAbs), fusion proteins and new molecular entities (NME) places a greater need on using these approaches, even at early stages of process and product development. This is due, in part, to a lack of available platform processes that have been the bedrock of accelerated monoclonal antibody development timelines for both gene to investigational new drug (IND) application and IND to biologics license application (BLA). Development paths have been reported to be further accelerated in response to the COVID-19 pandemic, with the potential to reduce gene to IND timelines to only six months.2 The path from IND to BLA for new molecular formats is a far greater challenge, without the years of platform process understanding and the increased number of product quality attributes. With an increased number of products on accelerated regulatory approval pathways this puts increased pressure on CMC development to support shortened BLA submission timelines. This is the point at which mass spectrometry (MS) can be leveraged to accelerate and de-risk product and process development.

Applying these advanced MS methods offers the potential to accelerate product development by shortening process characterisation timelines

MS is a widely used and powerful analytical technique for characterising and monitoring multiple product quality attributes and impurities of therapeutic proteins and is an enabling tool to ensure product quality, safety and efficacy. However, realising its potential means utilising the advanced methods available in the industry today and doing so at a sufficiently early stage to prevent costly setbacks and delays on your path to market.

Advanced MS methods offer improved data and speed

Analytical characterisation is a crucial part of the drug development process, as it can provide vital information about the specific characteristics of a product and their impact on clinical performance. Through careful evaluation of this information, CMC scientists can make informed decisions about risk mitigation strategies during development and manufacturing that safeguard functionality and, thus, effectiveness. A manufacturer that can demonstrate an in-depth understanding of its product and process will have the best chance of minimising risks during product development. While the approval of any product is based on the totality of data in the filing, a strong demonstration of overall product knowledge can expedite regulatory review. Conversely, poor analytical characterisation will likely lead to questions from regulators and, without sufficient product and process knowledge, an IND or BLA that is eventually deemed incomplete. Avoiding this scenario requires the utilisation of high‑throughput tools and techniques, such as advanced MS methods, that can help accelerate and de-risk product development. Technological improvements with this instrumentation have led to improved data quality and made them more accessible and applicable throughout the drug development lifecycle.

Supporting process development and characterisation with advanced MS

As MS technology has advanced over the years, this has led to significant increases in system sensitivity and accuracy, which allows for deeper and more accurate sample analysis. This is especially advantageous for molecules that are highly heterogeneous, as these are usually far more difficult to analyse using traditional methods. MS-based techniques, such as peptide mapping or a multi-attribute method (MAM), allow users to simultaneously monitor and quantify molecular attributes with just a single method. This improves efficiency by eliminating multiple analytical methods that would otherwise be needed for process characterisation.3 Applying these advanced MS methods offers the potential to accelerate product development by shortening process characterisation timelines. This approach is useful for new molecular formats where the overall analytical method burden is high and where data‑driven decisions are needed and waiting for the analytical data becomes the rate limiting step for a project.

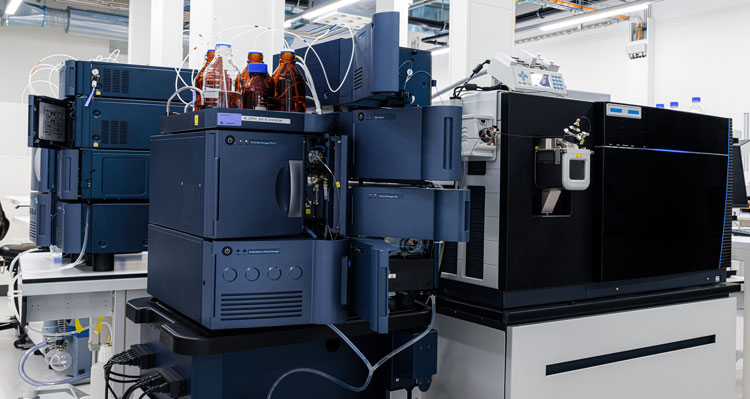

Mass spectrometry system combined with nano-LC to maximise sensitivity for sequence variant workflow in Lonza Slough, UK. [Copyright Lonza 2023]

An orthogonal analytical approach is key to maximising product understanding and investing in the development of native intact MS workflows to complement peptide mapping and denaturing intact mass workflows is a key enabler. In comparison to denaturing intact MS analysis post reverse phase column desalting with high percentage of volatile organic solvents, native intact MS analysis is performed under near native conditions. It can follow either liquid chromatography (LC) or capillary electrophoresis (CE) separation in aqueous solution at near-neutral pH. Use of volatile salts maintains the quaternary structures of multiple-chain proteins or antibodies; preserves non-covalent interactions of protein complexes; retains high degrees of protein folding; and minimises the risk of artificial post-translational modifications. In addition, native intact MS is very powerful for protein chain assembly analysis and protein isoforms analysis.

The complex challenge of sequence variants

One example where the application of advanced mass spectrometry methods can have a considerable impact on product characterisation is with sequence variants (SVs). The growing presence of these unintended amino acid sequences in recombinant proteins is a top concern for regulators and drug manufacturers due to the ability of these mutations to cause higher order structural problems, potentially affecting efficacy and safety.

While SVs are typically present at less than 0.1 percent in natural proteins, a concerted effort across the industry to improve titer and productivity during scaleup using intensified bioreactor manufacturing systems can put added stress on production cell lines.4 In some cases recombinantly expressed proteins have been observed to contain higher levels of SV, and these can be difficult to remove by the manufacturing purification process. Incorrect DNA sequences can also lead to high levels of SVs. However, the heightened sensitivity of advanced MS methods allows process developers to test more samples at the cell line development stage, facilitating the detection of SVs and preventing problematic clones from entering a late‑phase programme. The risk is higher for multi‑specific antibodies, fusion proteins and NMEs, where repeating sequences are more common, particularly as these can be used in flexible linker regions. Investing in appropriate MS hardware and software to detect SVs is vital to avoid false positive and negative results. At Lonza we have found that de novo amino acid sequencing alongside comprehensive peptide alignment tools gives the highest confidence in SV data.

Characterisation of post-translational modifications relevant to drug product formulation

Formulatability studies of biopharmaceutical drug products apply several types of forced stress conditions, such as UV light, chemical oxidation, high temperature, high and low pH. The main purpose of such studies is to predict potential liabilities in the active protein and implications on its stability during long-term storage, or even earlier during the manufacturing and purification process. However, such stress can lead to post‑translational modifications (PTMs) of the active protein, which might be detrimental to the medication’s efficacy if they occur in protein regions that are relevant for binding to an antigen (eg, complementarity‑determining regions of mAbs). Therefore, it is important to identify the sites of PTMs or peptide bond fragmentation that could contribute to product instability.

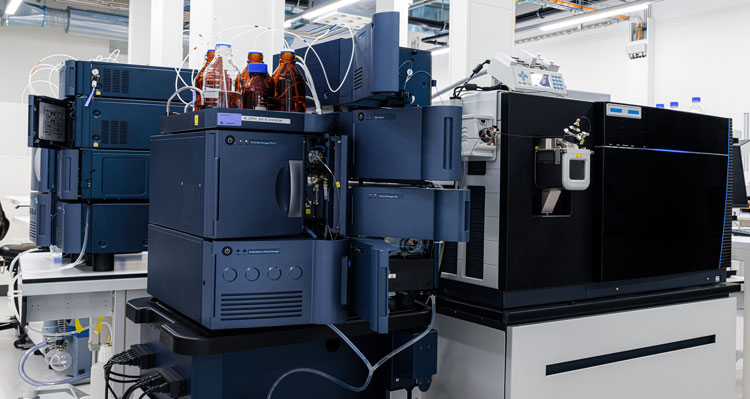

Lonza’s MS and chromatography capabilities in Visp, Switzerland. Flexible design to allow for multiple complex protein characterisation workflows. {Copyright Lonza 2023}

So far, mass spectrometry is the most appropriate analytical technique capable of performing this task. There is a need to develop a platform MS method that is capable of simultaneously identifying degradation products and quantifying several PTMs in the context of CQA with rapid turnaround time. In addition, use of a high‑sensitivity mass spectrometry setup (nano LC-MS) for quantification of low-level PTMs enables the design of appropriate stress panels that are representative of the formulation’s experienced stress conditions. This information gives insight into whether a developed formulation would be sufficiently stable, or if reformulation is necessary to enhance stability. The best approach is to combine MS with other physicochemical analytical techniques to accelerate comparability assessment and de-risk formulation development. Approaching characterisation of complex molecules from both a drug product and drug substance perspective in a holistic manner, with previous technical experience combined with cutting edge technologies, can enable delivery of successful CMC outcomes.

About the authors

Ian is a Senior Technical Leader in the Global Biologics Technical Development team at Lonza. He has over 15 years’ experience in mass spectrometry, focusing on analytical characterisation strategies for numerous complex recombinant proteins, NME and AAV from pre-clinical through to commercial. Ian has previously worked for Allergan, AbbVie and Pharmaron gene therapy.

Mostafa Zarei, PhD

Mostafa leads the protein characterisation group at Lonza drug product services (DPS) in Basel. Since 2014, he has worked in biopharmaceutical analysis, focusing on the design and implementation of different analytical strategies for analysis of therapeutic proteins, mAbs and ADCs using mass spectrometry. He received his PhD in Analytical Chemistry in

2009 from University of Muenster, followed by a post-doctoral research in Freiburg University where he expanded his knowledge in proteomics.

Qifeng Zhang, PhD

Qifeng is a Global Senior Principal Scientist at Lonza. Qifeng focuses on understanding molecules to design knowledge-driven CMC strategies for product and process development of novel molecular format protein products from lead molecule optimisation to commercial release. He holds a BSc in biology and a PhD in analytical organic chemistry.

References

- Available from: https://database.ich.org/sites/default/files/Q8_R2_Guideline.pdf.

- Kelley B. Developing therapeutic monoclonal antibodies at pandemic pace. Nat Biotechnol. 2020; 38, 540-545.

- Rogers RS, Nightlinger NS, Livingston B, et al. Development of a quantitative mass spectrometry multi-attribute method for characterization, quality control testing and disposition of biologics. MAbs. 2015; 7(5): 881-90.

- Zhang A, Chen Z, Li M, et al. A general evidence-based sequence variant control limit for recombinant therapeutic protein development. MAbs. 2020; 12(1): 1791399.

Issue

Related topics

Analytical techniques, Biologics, Bioprocessing, Chromatography, Drug Development, Mass Spectrometry, QA/QC, Quality by Design (QbD), Spectroscopy